Unveiling the Mechanics: The Vital Role of Boost Pressure & Temperature Sensors

Brief Overview of Boost Pressure & Temperature Sensor

Boost pressure and temperature sensors are critical components in modern automotive and industrial systems. These sensors play a pivotal role in measuring and regulating the pressure and temperature levels within various systems, ensuring optimal performance and efficiency.

Importance in Automotive and Industrial Applications

In both automotive and industrial settings, the accurate monitoring of boost pressure and temperature is paramount. These sensors provide real-time data that helps in optimizing engine performance, enhancing fuel efficiency, and ensuring the longevity of machinery. In automotive applications, such sensors are integral to turbocharged engines, where precise control of boost pressure is essential for achieving optimal power output without compromising on fuel consumption. Similarly, in industrial applications such as manufacturing processes or power generation, maintaining specific pressure and temperature levels is crucial for operational efficiency and product quality.

Significance of Monitoring Boost Pressure and Temperature

The significance of monitoring boost pressure and temperature cannot be overstated. Fluctuations in these parameters can lead to various issues such as engine knock, overheating, reduced power output, and even mechanical failures. By continuously monitoring boost pressure and temperature, potential problems can be identified and addressed promptly, preventing costly repairs and downtime. Moreover, optimizing these parameters can result in improved performance, fuel efficiency, and overall operational reliability, making boost pressure and temperature sensors indispensable in today’s automotive and industrial applications.

Fundamentals of Boost Pressure & Temperature Sensor

Definition and Functionality

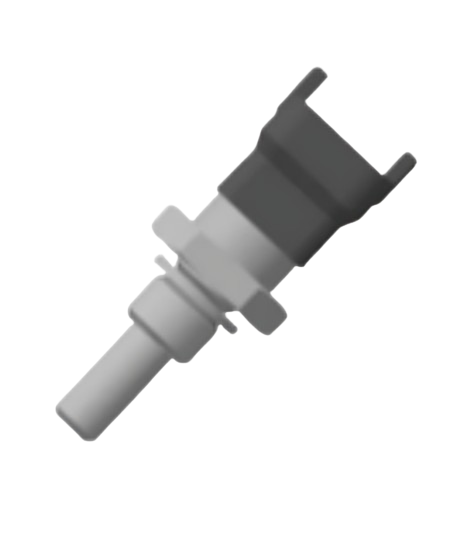

Boost pressure and temperature sensors are devices designed to measure the pressure and temperature levels in a system, typically an engine or industrial machinery. Their primary function is to provide accurate data regarding these parameters, which are crucial for maintaining optimal performance and preventing potential damage or failures.

Types of Sensors Available

- Mechanical Sensors: Mechanical boost pressure and temperature sensors rely on physical mechanisms to measure pressure and temperature changes. These sensors often utilize diaphragms, springs, and mechanical linkages to convert pressure and temperature variations into mechanical movements, which are then translated into electrical signals.

- Electronic Sensors: Electronic boost pressure and temperature sensors utilize advanced electronic components such as semiconductor elements or piezoelectric materials to directly measure pressure and temperature changes. These sensors offer higher accuracy, faster response times, and greater versatility compared to mechanical sensors.

Operating Principles

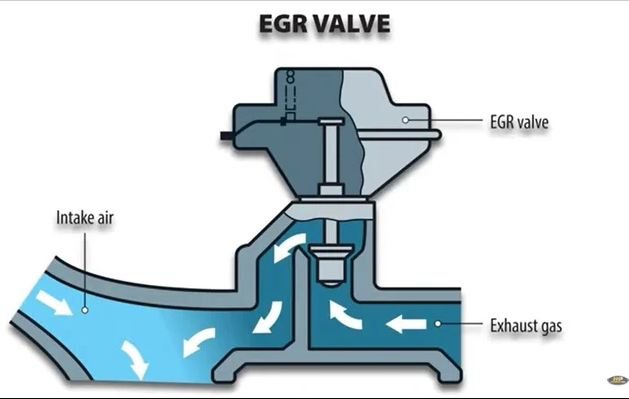

- Boost Pressure Measurement: Boost pressure measurement is typically achieved through the use of pressure transducers or sensors. These sensors detect the pressure difference between the intake manifold and the surrounding atmosphere, providing crucial data for engine management systems. In turbocharged engines, boost pressure sensors play a vital role in regulating turbocharger operation to optimize performance and fuel efficiency.

- Temperature Sensing: Temperature sensing in boost pressure and temperature sensors can be accomplished using various methods, including thermistors, resistance temperature detectors (RTDs), or thermocouples. These sensors measure the temperature of the intake air or engine coolant, providing valuable information for fuel injection timing, ignition timing, and emissions control.

Components and Construction

Boost pressure and temperature sensors typically consist of several key components, including:

- Sensing Element: This is the component responsible for directly measuring pressure or temperature changes.

- Housing: The housing encloses and protects the sensing element from external environmental factors such as dust, moisture, and vibration.

- Electrical Connections: These allow the sensor to interface with the electronic control unit (ECU) or monitoring system.

- Signal Conditioning Circuitry: In electronic sensors, signal conditioning circuitry processes the raw sensor data and outputs a standardized electrical signal proportional to the measured parameter.

- Sealing: Sealing materials ensure that the sensor remains watertight and resistant to contamination, enhancing its durability and reliability in harsh operating conditions.

The construction of boost pressure and temperature sensors may vary depending on the specific application and performance requirements, but they all share these fundamental components to enable accurate and reliable measurement capabilities.

Applications of Boost Pressure & Temperature Sensors

A. Automotive Sector

- Turbocharged Engines: Boost pressure and temperature sensors are extensively used in turbocharged engines to monitor and regulate the amount of boost pressure generated by the turbocharger. By accurately measuring the boost pressure, these sensors enable the engine management system to adjust fuel delivery and ignition timing, optimizing performance while ensuring reliability and efficiency.

- Performance Tuning and Monitoring: In high-performance automotive applications, boost pressure and temperature sensors play a crucial role in performance tuning and monitoring. Enthusiasts and tuners rely on these sensors to fine-tune engine parameters and maximize power output while maintaining safe operating conditions. Additionally, these sensors provide valuable data for diagnosing and troubleshooting engine issues, helping mechanics and technicians optimize vehicle performance.

B. Industrial Machinery

- Compressors and Turbines: Boost pressure and temperature sensors are integral components of industrial compressors and turbines, where they monitor and control the pressure and temperature levels during operation. By ensuring precise control over these parameters, these sensors help optimize energy efficiency, minimize downtime, and prolong equipment lifespan in various industrial applications such as power generation, air compression, and gas processing.

- HVAC Systems: In heating, ventilation, and air conditioning (HVAC) systems, boost pressure and temperature sensors play a vital role in maintaining optimal indoor air quality and comfort. These sensors monitor the pressure and temperature of the refrigerant and airflow within HVAC systems, allowing for precise control over heating, cooling, and ventilation processes. By ensuring efficient operation and temperature regulation, these sensors contribute to energy savings and enhanced occupant comfort in residential, commercial, and industrial buildings.

C. Aerospace Industry

- Aircraft Engines: Boost pressure and temperature sensors are critical components of aircraft engines, where they monitor and regulate the intake air pressure and temperature. In aviation applications, maintaining precise control over these parameters is essential for engine performance, fuel efficiency, and aircraft safety. Boost pressure and temperature sensors enable the engine control system to optimize fuel-air mixture ratios, manage engine thrust levels, and ensure reliable operation in various flight conditions.

- Spacecraft Propulsion Systems: In spacecraft propulsion systems, boost pressure and temperature sensors play a vital role in monitoring and controlling the performance of rocket engines and thrusters. These sensors provide real-time data on propellant pressure and temperature, allowing for precise control over propulsion maneuvers and spacecraft trajectory adjustments. By ensuring accurate measurement and regulation of boost pressure and temperature, these sensors contribute to the success of space missions and spacecraft operations in the harsh environment of space.

Importance of Accurate Monitoring

Engine Efficiency and Performance

Accurate monitoring of boost pressure and temperature is crucial for optimizing engine efficiency and performance. By precisely regulating the intake air pressure and temperature, engines can achieve optimal combustion conditions, resulting in improved power output, throttle response, and overall drivability.

Preventing Damage and Failure

Effective monitoring of boost pressure and temperature helps prevent potential damage and failure within the engine system. Fluctuations or abnormalities in these parameters can lead to engine knock, overheating, and mechanical stress, which may result in costly repairs or even catastrophic failures. Timely detection and correction of such issues through accurate monitoring can significantly extend the lifespan of engine components and ensure reliable operation.

Fuel Efficiency and Emissions Control

Accurate monitoring of boost pressure and temperature also contributes to fuel efficiency and emissions control. By maintaining precise control over combustion parameters, such as air-fuel ratio and ignition timing, engines can achieve optimal fuel combustion, minimizing fuel consumption and reducing harmful emissions. Additionally, monitoring these parameters allows for the timely detection of any deviations from desired operating conditions, enabling adjustments to be made to optimize fuel efficiency and emissions performance.

Challenges and Solutions

Sensor Accuracy and Calibration

One of the primary challenges in boost pressure and temperature monitoring is ensuring sensor accuracy and calibration. Variations in sensor performance or calibration errors can lead to inaccurate measurements, compromising engine performance and reliability. Regular sensor calibration and quality control measures are essential to ensure accurate and reliable monitoring.

Environmental Conditions

Boost pressure and temperature sensors are often exposed to harsh environmental conditions, including high temperatures, vibrations, and contaminants. These conditions can affect sensor performance and longevity if not adequately addressed. Solutions such as robust sensor housings, protective coatings, and environmental sealing can help mitigate the impact of environmental factors on sensor reliability and accuracy.

Durability and Reliability

Boost pressure and temperature sensors must withstand the rigors of automotive and industrial environments, where they may be subjected to mechanical stress, thermal cycling, and chemical exposure. Ensuring the durability and reliability of sensors requires robust design and construction, as well as thorough testing under simulated operating conditions to identify and address potential failure modes.

Integration with Vehicle Systems

Integrating boost pressure and temperature sensors with vehicle systems poses another challenge, particularly in modern automotive applications with complex electronic control systems. Seamless integration requires compatibility with existing vehicle interfaces and communication protocols, as well as reliable data transmission and processing capabilities. Close collaboration between sensor manufacturers and vehicle manufacturers is essential to ensure successful integration and optimal performance in real-world driving conditions.

Advancements in Boost Pressure & Temperature Sensor Technology

Miniaturization and Integration

Advancements in boost pressure and temperature sensor technology have led to miniaturization and integration, enabling more compact and lightweight sensor designs. Miniaturization allows for easier integration into tight engine compartments and industrial machinery, while integrated sensors simplify installation and reduce wiring complexity. These advancements contribute to overall system efficiency and reliability.

Wireless Monitoring Systems

The development of wireless monitoring systems has revolutionized boost pressure and temperature monitoring, especially in automotive applications. Wireless sensors eliminate the need for physical wiring, enabling flexible installation and reducing installation time and cost. Moreover, wireless connectivity enables real-time data transmission to onboard computers or mobile devices, facilitating remote monitoring and diagnostics.

Enhanced Data Processing and Analysis

Advancements in data processing and analysis capabilities have improved the functionality of boost pressure and temperature sensors. Modern sensors are equipped with advanced signal processing algorithms and onboard microcontrollers, allowing for real-time data analysis and adaptive control strategies. Enhanced data processing capabilities enable more precise control over engine parameters and better optimization of performance and efficiency.

Future Trends and Developments

AI and Machine Learning Applications

The integration of Artificial intelligence (AI) and machine learning algorithms holds great promise for the future of boost pressure and temperature sensor technology. AI-powered sensor systems can learn from data patterns and historical trends, enabling predictive maintenance, fault detection, and optimization of engine performance. AI algorithms can also optimize sensor calibration and compensation for environmental variations, further improving sensor accuracy and reliability.

Sensor Fusion Technology

Sensor fusion technology, which combines data from multiple sensors to enhance accuracy and reliability, is expected to play a significant role in future boost pressure and temperature monitoring systems. By integrating data from various sensors such as pressure, temperature, and airflow sensors, sensor fusion algorithms can provide a more comprehensive understanding of engine conditions and enable more robust control strategies.

Smart Maintenance and Predictive Analytics

The adoption of smart maintenance and predictive analytics solutions is anticipated to revolutionize how boost pressure and temperature sensors are managed and maintained. By analyzing sensor data trends and performance metrics, predictive analytics algorithms can identify potential issues before they escalate into failures, enabling proactive maintenance and minimizing downtime. Smart maintenance systems can also optimize sensor calibration schedules and recommend preventive measures to maximize sensor lifespan and reliability.

Conclusion

Boost pressure and temperature sensors play a vital role in automotive, industrial, and aerospace applications by monitoring critical parameters to optimize performance, ensure reliability, and prevent damage. In this article, we explored the fundamentals, applications, challenges, advancements, and future trends of boost pressure and temperature sensor technology.

Outlook for Boost Pressure & Temperature Sensor Technology

The future of boost pressure and temperature sensor technology is promising, with ongoing advancements in miniaturization, wireless connectivity, data processing, and predictive analytics. As AI, machine learning, and sensor fusion technologies continue to evolve, boost pressure and temperature sensors will become more intelligent, reliable, and capable of supporting increasingly sophisticated control and diagnostic functions.

Importance of Continuous Innovation and Improvement

Continuous innovation and improvement are essential to meet the evolving demands of automotive, industrial, and aerospace industries. By investing in research and development, sensor manufacturers can address current challenges, explore new opportunities, and drive technological advancements that enhance the performance, reliability, and functionality of boost pressure and temperature sensors.