The Importance of DPF Regeneration Switch in Vehicle Maintenance

Understanding DPF (Diesel Particulate Filter)

In the realm of vehicle emissions control, the Diesel Particulate Filter (DPF) stands out as a critical component. Designed to capture and trap harmful particulate matter emitted by diesel engines, the DPF plays a pivotal role in reducing environmental pollution.

Exploring DPF Regeneration

DPF regeneration is a vital process aimed at maintaining the efficiency of the DPF. Over time, as particulate matter accumulates within the filter, it becomes necessary to initiate regeneration to prevent clogging and ensure optimal engine performance. This process involves burning off accumulated soot to restore the filter’s functionality.

The Need for a DPF Regeneration Switch

Despite the significance of DPF regeneration, conventional systems lack the flexibility to control this process manually. This limitation poses challenges, especially in situations where immediate regeneration is required for enhanced vehicle performance. Introducing a DPF regeneration switch addresses this issue, offering drivers greater control over the regeneration cycle to optimize engine efficiency.

Understanding DPF Regeneration

Trapping Harmful Particulate Matter

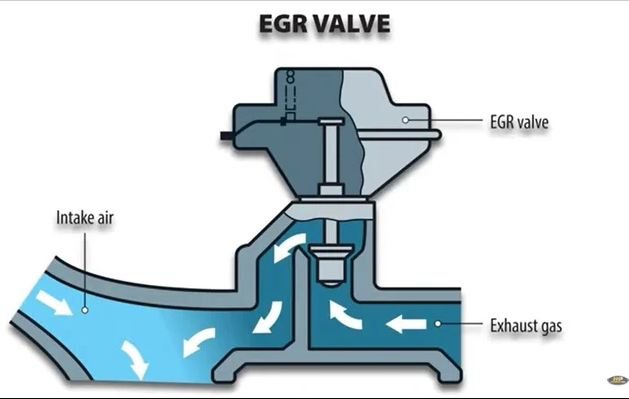

The DPF (Diesel Particulate Filter) serves as a formidable barrier against the emission of harmful particulate matter from diesel engines. As exhaust gases pass through the filter, tiny particles, including soot and ash, are captured within its porous structure. This mechanism plays a crucial role in mitigating environmental pollution by preventing these pollutants from being released into the atmosphere.

Process of Regeneration

Over time, the accumulation of particulate matter within the DPF can lead to a decrease in engine efficiency and performance. To counteract this, regeneration becomes imperative. During regeneration, the trapped particles are oxidized and converted into less harmful substances, such as carbon dioxide and water vapor. This process effectively clears the accumulated particles, restoring the DPF’s ability to capture pollutants and ensuring optimal engine functionality.

Challenges and Importance of Active Regeneration

Passive regeneration, which occurs naturally during driving conditions where exhaust temperatures are sufficiently high, is often inadequate, particularly in urban driving scenarios or during short trips where exhaust temperatures may not reach the required levels. This inadequacy underscores the importance of active regeneration methods, which involve the introduction of additional heat into the exhaust system to facilitate the regeneration process. Active regeneration ensures timely and thorough cleaning of the DPF, preventing issues such as filter blockage and maintaining optimal engine performance.

The Role of DPF Regeneration Switch

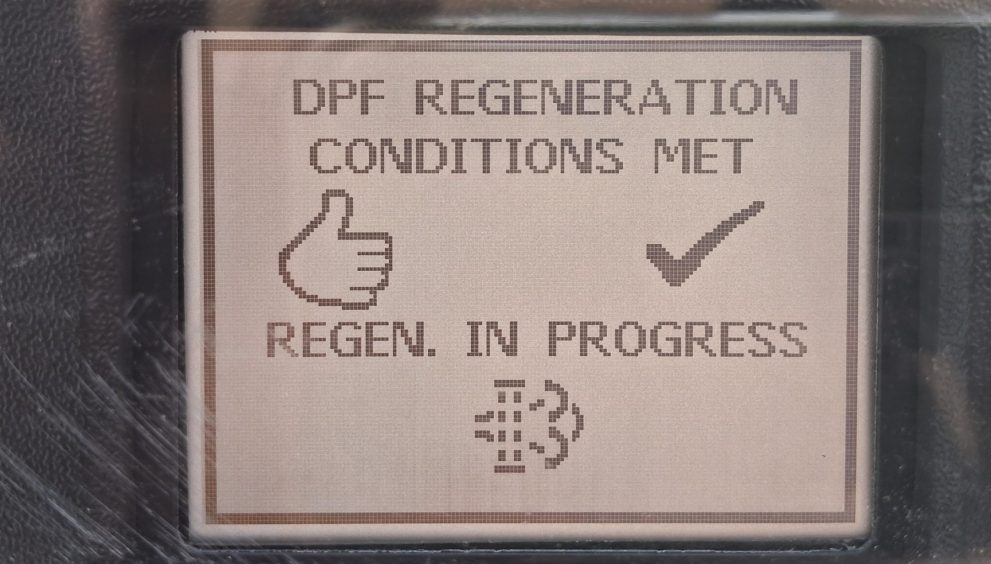

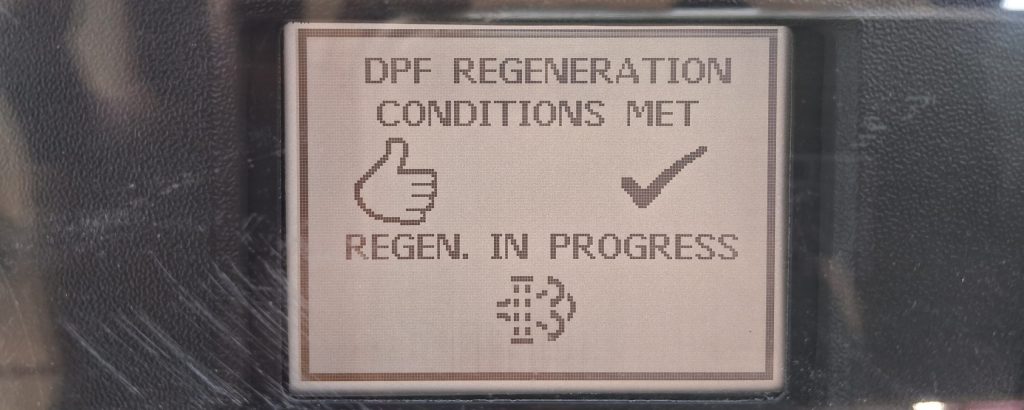

Understanding the DPF Regeneration Switch

The DPF regeneration switch is a specialized control mechanism integrated into modern diesel vehicles, granting drivers the ability to manually initiate the regeneration process. This switch allows users to take active control over when regeneration occurs, providing flexibility and optimization opportunities for maintaining engine health. DPF Regeneration Switch Also calls DPF Regeneration Control

Importance of Manual Control (DPF Regeneration Switch)

Manual control over regeneration cycles through the DPF regeneration switch offers significant advantages for vehicle efficiency. Unlike passive regeneration, which relies on specific driving conditions to trigger the process, manual activation ensures that regeneration occurs precisely when needed. This level of control is particularly beneficial in urban driving settings or during short trips, where exhaust temperatures may not naturally reach the required levels for passive regeneration. By allowing drivers to initiate regeneration proactively, the DPF regeneration switch enhances engine performance and prolongs the lifespan of critical emission control components.

Benefits of Timely Regeneration Activation

The timely activation of regeneration using the DPF regeneration switch plays a pivotal role in preventing a myriad of engine issues. By promptly clearing the accumulated particulate matter from the DPF, the switch helps maintain optimal exhaust flow and prevents filter blockages. This, in turn, safeguards against potential power loss, increased fuel consumption, and costly repairs associated with DPF-related malfunctions. Additionally, regular regeneration activation via the switch promotes cleaner emissions, contributing to environmental sustainability while ensuring compliance with stringent emissions regulations.

Advantages of Manual DPF Regeneration Switch

Enhanced Fuel Efficiency and Reduced Maintenance Costs

Manual control over DPF regeneration enables drivers to initiate the process at opportune moments, leading to enhanced fuel efficiency. By proactively clearing accumulated particulate matter from the filter, the engine operates more efficiently, resulting in reduced fuel consumption over time. Moreover, by preventing excessive soot buildup, manual regeneration helps minimize wear and tear on engine components, ultimately lowering maintenance costs associated with DPF-related issues.

Prevention of Potential DPF Clogging and Associated Engine Damage

One of the primary advantages of manual DPF regeneration control is the mitigation of potential DPF clogging and associated engine damage. By allowing drivers to intervene and initiate regeneration when necessary, the risk of excessive soot accumulation leading to filter blockage is significantly reduced. This proactive approach prevents potential engine performance degradation, loss of power, and costly repairs stemming from DPF-related malfunctions. DPF Regeneration Switch

Control Over Regeneration Timing for Optimal Performance

The manual DPF regeneration control provides drivers with the flexibility to tailor regeneration timing according to specific driving conditions. Whether navigating urban environments with frequent stop-and-go traffic or embarking on long highway journeys, drivers can optimize regeneration cycles to suit varying operational demands. This level of control ensures that the regeneration process aligns with the engine’s performance needs, maintaining optimum power delivery and responsiveness across different driving scenarios. Ultimately, by exerting control over regeneration timing, drivers can maximize vehicle performance and overall driving experience.

Addressing Common Concerns

Safety Considerations and Precautions with DPF Regeneration

Safety is paramount when it comes to DPF regeneration, and certain precautions should be observed to mitigate potential risks. During regeneration, exhaust temperatures can rise significantly, posing a fire hazard if flammable materials are present near the exhaust system. Therefore, it’s crucial to avoid parking over dry grass or leaves and ensure proper ventilation when initiating regeneration, especially in enclosed spaces. Additionally, drivers should be mindful of hot exhaust components and refrain from touching them immediately after regeneration. By adhering to safety guidelines and exercising caution, the risks associated with DPF regeneration can be effectively minimized.

Compatibility and Adaptability of Regeneration Switches

Regeneration switches are designed to be compatible and adaptable across a wide range of vehicle models equipped with DPF systems. Manufacturers prioritize standardization and interoperability to ensure that regeneration switches seamlessly integrate into various vehicle control systems. While slight differences may exist in the placement or design of the switch among different models, its fundamental functionality remains consistent. This compatibility ensures that drivers can enjoy the benefits of manual DPF regeneration control regardless of their vehicle make or model.

Addressing Misconceptions and Myths

Despite the proven benefits of manual DPF regeneration control, several misconceptions and myths persist surrounding this process. One common misconception is that manual regeneration is unnecessary, as passive regeneration occurs naturally during driving. However, passive regeneration may be insufficient in certain driving conditions, making manual intervention essential for maintaining optimal DPF performance. Another myth is that manual regeneration increases fuel consumption and engine wear. In reality, properly timed regeneration enhances fuel efficiency by preventing excessive soot buildup and prolongs engine lifespan by reducing stress on engine components. By dispelling these misconceptions and educating drivers on the benefits of manual DPF regeneration control, we can promote safer, more efficient driving practices.

Future Outlook and Innovations

Advancements in DPF Regeneration Technology

The future of DPF regeneration technology is characterized by continuous innovation aimed at enhancing efficiency and sustainability. Manufacturers are investing in advanced materials and design concepts to improve the performance and durability of DPF systems. Nanotechnology and advanced catalyst coatings are being explored to enhance filtration efficiency and reduce regeneration frequency. Additionally, developments in predictive analytics and sensor technology enable real-time monitoring of DPF performance, facilitating proactive maintenance and optimizing regeneration cycles for maximum effectiveness.

Integration of Smart Features and Automation

The integration of smart features and automation holds immense potential for revolutionizing DPF regeneration control. Future vehicles may incorporate artificial intelligence and machine learning algorithms to analyze driving patterns and environmental conditions, automatically triggering regeneration when necessary. Smart connectivity solutions enable remote monitoring and control of regeneration cycles via smartphone apps or vehicle telematics systems, providing drivers with greater convenience and peace of mind. Furthermore, emerging technologies such as vehicle-to-infrastructure communication may enable dynamic regeneration scheduling based on traffic conditions and emissions regulations, further optimizing DPF performance and reducing environmental impact.

Evolution of Emission Control and Vehicle Design

The evolving landscape of emission control is driving significant changes in vehicle design and engineering practices. Stricter emissions regulations worldwide are prompting automakers to prioritize the development of cleaner and more efficient propulsion systems. Electric and hybrid powertrains are gaining traction as viable alternatives to traditional internal combustion engines, offering zero-emission driving solutions. Additionally, advancements in exhaust aftertreatment technologies, including selective catalytic reduction (SCR) and lean NOx traps, are enabling further reductions in harmful emissions from diesel vehicles. As emission standards continue to tighten, we can expect to see continued innovation in emission control technologies, shaping the future of vehicle design towards greater sustainability and environmental stewardship.

Related Diagnostic Trouble Codes (DTCs) often associated with DPF (Diesel Particulate Filter) regeneration issues include:

- P2002 – Diesel Particulate Filter Efficiency Below Threshold (Bank 1)

- This code indicates that the efficiency of the DPF has fallen below the acceptable threshold, often due to excessive soot accumulation. It typically triggers the Check Engine Light and may require regeneration to rectify.

- P2463 – Diesel Particulate Filter Restriction – Soot Accumulation

- This code signifies that the DPF has become restricted due to excessive soot accumulation. It indicates the need for regeneration to clear the accumulated particles and restore proper DPF function.

- P2459 – Diesel Particulate Filter Regeneration Frequency

- This code indicates that the regeneration frequency of the DPF is too high or too low compared to expected values. It suggests a potential issue with the regeneration system or driving conditions affecting regeneration efficiency.

- P2458 – Diesel Particulate Filter Regeneration Duration

- This code indicates that the duration of the DPF regeneration process is abnormal, either too long or too short. It may indicate a malfunction in the regeneration system or issues with the DPF itself.

- P246C – Diesel Particulate Filter Differential Pressure Sensor Circuit Low

- This code indicates a low voltage condition in the circuit of the DPF differential pressure sensor. It can affect the accuracy of DPF pressure readings, leading to improper regeneration or other performance issues.

- P246B – Diesel Particulate Filter Regeneration Control Stuck Closed

- This code suggests that the regeneration control valve is stuck closed, preventing proper airflow for regeneration. It can result in insufficient regeneration and may trigger other related DTCs.

These DTCs serve as indicators of potential issues related to DPF regeneration and underscore the importance of timely maintenance and troubleshooting to ensure proper DPF function and vehicle performance.

Conclusion – DPF Regeneration Switch

A. Importance of DPF Regeneration

In conclusion, DPF regeneration plays a crucial role in maintaining vehicle efficiency and controlling emissions. By clearing accumulated particulate matter from the Diesel Particulate Filter, regeneration ensures optimal engine performance while minimizing environmental pollution. This process is essential for preserving engine health and complying with stringent emissions regulations, making it a cornerstone of modern diesel vehicle technology.

B. Significance of DPF Regeneration Switch

The introduction of the DPF regeneration switch marks a significant advancement in empowering drivers to take control of their vehicle’s performance. By allowing manual initiation of regeneration cycles, the switch offers flexibility and optimization opportunities, particularly in challenging driving conditions. Drivers can proactively manage regeneration to enhance fuel efficiency, prevent engine damage, and ensure a smoother driving experience, underscoring the critical role of the switch in maximizing vehicle efficiency and longevity.

C. Call to Action – DPF Regeneration Switch

As we look towards a greener and more efficient automotive future, it is imperative for manufacturers and regulators to prioritize the adoption of DPF regeneration switch technology. By integrating this innovative feature into diesel vehicles as standard equipment, we can empower drivers to play an active role in emissions control and environmental stewardship. Furthermore, regulatory bodies should incentivize the implementation of DPF regeneration switches to accelerate their adoption across the automotive industry. Together, by embracing DPF regeneration switch technology, we can pave the way for a cleaner, more sustainable transportation ecosystem for generations to come. DPF Regeneration Switch

More Article Like- Revolutionizing Cooling Systems: The Rise of Electronic Viscous Fan Speed Sensors

FAQ

What is DPF regeneration, and why is it necessary?

DPF regeneration is the process of burning off accumulated soot particles from the Diesel Particulate Filter to maintain engine efficiency and reduce emissions. It’s necessary to prevent filter blockage, which can lead to reduced engine performance and increased emissions.

How does the DPF regeneration switch work?

The DPF regeneration switch allows drivers to manually initiate the regeneration process when needed, providing control over the cleaning cycle. By activating the switch, drivers can optimize engine performance and ensure proper DPF function.

What are the benefits of using a DPF regeneration switch?

Using a DPF regeneration switch offers several benefits, including enhanced fuel efficiency, reduced maintenance costs, and prevention of potential engine damage. It also provides drivers with control over regeneration timing for optimal performance in various driving conditions

Are there any safety concerns associated with DPF regeneration?

While DPF regeneration is generally safe, drivers should be cautious of high exhaust temperatures during the process. It’s essential to avoid parking over flammable materials and ensure proper ventilation when initiating regeneration, especially in enclosed spaces.

Is a DPF regeneration switch compatible with all vehicles?

DPF regeneration switches are designed to be compatible with a wide range of diesel vehicles equipped with DPF systems. However, compatibility may vary depending on vehicle make and model. It’s advisable to consult with the vehicle manufacturer or a qualified technician for specific compatibility information.