Unveiling the Importance of Crankshaft Position Sensors in Automotive Engines

In the intricate web of modern automotive engineering, sensors play a pivotal role in ensuring the seamless functioning of various components. Among these, the crankshaft position sensor emerges as a critical element, contributing significantly to the overall performance of a vehicle. This article delves into the depths of the crankshaft position sensors, shedding light on its importance in maintaining accurate engine timing and, consequently, optimizing vehicle performance.

Brief Overview of the Role of Sensors in Modern Automotive Engines

In the ever-evolving landscape of automotive technology, sensors have become indispensable components that facilitate the smooth operation of modern engines. These sensors serve as the eyes and ears of the vehicle, constantly monitoring and relaying crucial information to the engine control unit (ECU). This data, in turn, enables the ECU to make real-time adjustments, ensuring optimal efficiency, fuel economy, and performance.

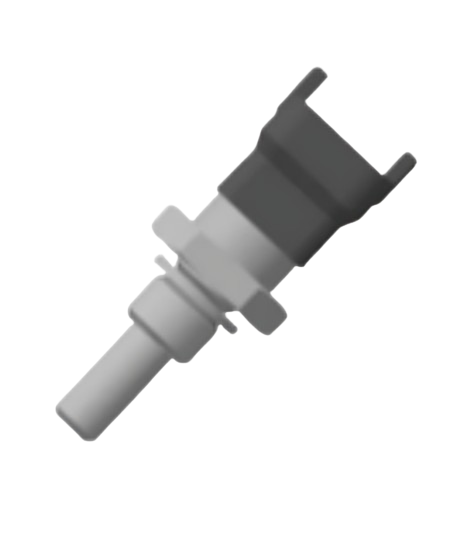

Introduction to the Crankshaft Position Sensor

Among the myriad sensors present in today’s automobiles, the crankshaft position sensor holds a key position. It is a device designed to monitor the rotational speed and position of the crankshaft in an internal combustion engine. By providing this vital information to the ECU, the crankshaft position sensor facilitates precise ignition timing and fuel injection.

Importance of Accurate Engine Timing in Vehicle Performance

Accurate engine timing is paramount for the smooth operation of a vehicle. The timing of ignition and fuel injection must be precisely coordinated to achieve efficient combustion, which directly influences power generation and fuel efficiency. The crankshaft position sensor plays a pivotal role in this synchronization, ensuring that the engine’s moving parts operate in harmony. Any deviation from the optimal timing can lead to decreased performance, increased emissions, and potential damage to the engine.

As we venture further into the intricacies of the crankshaft position sensor, we will explore its working mechanism, common issues, and the importance of timely maintenance in the subsequent sections of this comprehensive article.

Understanding Crankshaft Position Sensors

Definition and Purpose of Crankshaft Position Sensors

Crankshaft position sensors, commonly known as CKP sensors, are crucial components in modern automotive engines. Their primary purpose is to monitor the rotational speed and exact position of the crankshaft, which is vital information for the engine control unit (ECU). By providing real-time data on the crankshaft’s movement, these sensors enable the ECU to optimize ignition timing and fuel injection, ensuring efficient combustion and overall engine performance.

Types of Crankshaft Position Sensors

Crankshaft position sensors come in various types, each employing distinct technologies to fulfill their role. The three main types are:

- Hall Effect Sensors:

Hall Effect sensors utilize the Hall Effect phenomenon, where a voltage is generated when a magnetic field interacts with a semiconductor. These sensors are reliable and commonly used in automotive applications due to their durability and precision. - Optical Sensors:

Optical sensors use light beams to detect the position of the crankshaft. These sensors are known for their accuracy but can be sensitive to environmental factors such as dirt or oil. Regular maintenance is crucial to ensure their optimal performance. - Magnetoresistive Sensors:

Magnetoresistive sensors detect changes in the magnetic field’s resistance caused by the movement of the crankshaft. They offer a balance between the reliability of Hall Effect sensors and the precision of optical sensors, making them a popular choice in certain automotive systems.

How Crankshaft Position Sensors Work

Understanding the inner workings of crankshaft position sensors is essential for appreciating their role in the engine management system. The process involves two key steps:

- Detection of Crankshaft Position:

As the crankshaft rotates, the crankshaft position sensor detects the position of the crankshaft’s reluctor wheel or tone ring. This wheel is mounted on the crankshaft and features evenly spaced teeth or slots. The sensor identifies the gaps or teeth as the crankshaft turns, determining its exact position at any given moment. - Signal Transmission to the Engine Control Module (ECM):

Once the crankshaft position is identified, the sensor generates electrical signals corresponding to the crankshaft’s position. These signals are then transmitted to the Engine Control Module (ECM), also known as the Engine Control Unit (ECU). The ECM utilizes this information to precisely control the ignition timing and fuel injection, ensuring optimal engine performance under various operating conditions.

In the next section, we’ll delve deeper into the potential issues that can arise with crankshaft position sensors and the importance of regular maintenance to prevent disruptions in engine performance.

Significance of Crankshaft Position Sensors

Precise Engine Timing for Optimal Combustion

One of the paramount contributions of crankshaft position sensors is their role in achieving precise engine timing. Accurate timing of ignition and fuel injection is essential for optimal combustion within the engine cylinders. The data provided by the crankshaft position sensor allows the Engine Control Module (ECM) to determine the exact position of the crankshaft, facilitating the synchronization of these critical processes. This precision results in efficient power generation and ensures that the engine operates at its peak performance.

Contribution to Fuel Efficiency

Crankshaft position sensors play a crucial role in optimizing fuel efficiency. By enabling the ECM to adjust the timing of fuel injection in real-time based on the crankshaft’s position, these sensors help achieve a more efficient combustion process. This, in turn, enhances fuel economy, reducing the overall fuel consumption of the vehicle and contributing to a greener and more sustainable driving experience.

Impact on Emission Control

The precise control of engine timing, made possible by crankshaft position sensors, has a direct impact on emission control. Efficient combustion results in fewer unburned hydrocarbons and other pollutants being released into the atmosphere. In compliance with stringent emission standards, the use of crankshaft position sensors is instrumental in minimizing the environmental footprint of vehicles and ensuring cleaner air quality.

Role in Preventing Engine Misfires

Crankshaft position sensors play a crucial role in preventing engine misfires, a condition where the air-fuel mixture fails to ignite in one or more cylinders. By accurately detecting the position of the crankshaft, these sensors contribute to the proper timing of spark plug firing and fuel injection. This precision significantly reduces the likelihood of misfires, enhancing engine reliability and preventing potential damage to the catalytic converter and other engine components.

Ensuring Smooth and Reliable Engine Operation

Ultimately, the overarching significance of crankshaft position sensors lies in their contribution to the overall smooth and reliable operation of the engine. By providing real-time data on the crankshaft’s position, these sensors empower the ECM to make instantaneous adjustments, ensuring that the engine functions seamlessly under various driving conditions. This reliability not only enhances the driving experience but also extends the lifespan of the engine, minimizing the risk of unexpected breakdowns and repairs.

As we proceed, the article will delve into common issues associated with crankshaft position sensors and offer insights into effective troubleshooting and maintenance practices to ensure prolonged and trouble-free functionality.

Common Symptoms of Crankshaft Position Sensor Issues

Engine Starting Problems

One of the primary indicators of crankshaft position sensor issues is difficulty in starting the engine. A malfunctioning sensor may fail to provide accurate information to the Engine Control Module (ECM), leading to incorrect ignition timing and fuel injection. This, in turn, can result in prolonged cranking times, intermittent starting, or, in severe cases, a complete inability to start the engine.

Stalling or Sudden Engine Shutdown

Crankshaft position sensor problems can manifest in instances of stalling or sudden engine shutdown while the vehicle is in motion. If the sensor fails to relay accurate data to the ECM, it can disrupt the engine’s timing, causing irregular combustion and, ultimately, leading to engine stall. This abrupt shutdown can pose safety hazards, especially during driving conditions that require constant power delivery.

Poor Acceleration and Performance

A compromised crankshaft position sensor can negatively impact the vehicle’s acceleration and overall performance. Inaccurate timing information can lead to suboptimal combustion, resulting in reduced power output and sluggish acceleration. Drivers may experience a noticeable decrease in engine performance, responsiveness, and overall driving satisfaction.

Check Engine Light (CEL) Activation

An illuminated Check Engine Light (CEL) on the dashboard is a common indication of potential issues with the crankshaft position sensor. Modern vehicles are equipped with onboard diagnostics that monitor various engine components, including sensors. If the ECM detects irregularities in the data provided by the crankshaft position sensor, it triggers the CEL to alert the driver to a potential problem.

Diagnostic Methods to Identify Sensor Malfunctions

Diagnosing crankshaft position sensor malfunctions involves a combination of visual inspection and electronic testing. Here are some diagnostic methods:

- Visual Inspection:

Examine the sensor and its wiring for any signs of physical damage, corrosion, or loose connections. Damaged wires or connectors can impede the sensor’s functionality. - OBD-II Scanner:

Use an OBD-II scanner to retrieve diagnostic trouble codes (DTCs) from the vehicle’s ECM. Specific codes related to crankshaft position sensor issues can provide valuable insights into the nature of the problem. - Multimeter Testing:

Measure the sensor’s electrical resistance with a multimeter to ensure it falls within the manufacturer’s specified range. Deviations from this range may indicate a faulty sensor. - Scope Testing:

Use an oscilloscope to observe the waveform produced by the crankshaft position sensor. An irregular or distorted waveform can suggest sensor malfunctions. - Crankshaft Position Sensor Replacement:

If all else fails, replacing the sensor with a new, quality component can often resolve issues related to faulty crankshaft position sensors.

In the upcoming section, we will explore preventive measures and maintenance practices to mitigate the risk of crankshaft position sensor failures and ensure the prolonged reliability of your vehicle’s engine.

Importance in Modern Engine Management Systems

Integration with Electronic Control Units (ECUs)

Crankshaft position sensors play a pivotal role in the seamless integration of modern engine management systems. These sensors are an integral part of the Electronic Control Units (ECUs) that govern and regulate various aspects of engine operation. The real-time data provided by crankshaft position sensors is essential for the precise control of ignition timing and fuel injection, allowing the ECU to make instantaneous adjustments for optimal engine performance.

Adaptive Engine Control Based on Sensor Data

The data relayed by crankshaft position sensors serves as a foundation for adaptive engine control strategies. Modern ECUs are designed to adapt to changing driving conditions, ensuring optimal performance, fuel efficiency, and emissions under diverse scenarios. By continuously monitoring the crankshaft’s position, the sensor enables the ECU to dynamically adjust parameters such as air-fuel mixture, ignition timing, and valve timing. This adaptability not only enhances overall engine efficiency but also contributes to a smoother and more responsive driving experience.

Role in Advanced Engine Technologies (e.g., Variable Valve Timing)

Crankshaft position sensors are integral components in facilitating advanced engine technologies, such as Variable Valve Timing (VVT). VVT systems adjust the timing of the opening and closing of the engine’s valves, optimizing efficiency across a range of operating conditions. The precise data provided by the crankshaft position sensor is crucial for coordinating the timing of the camshaft and, consequently, implementing variable valve timing strategies. This technology not only improves fuel efficiency but also enhances power delivery and reduces emissions, showcasing the multifaceted role of crankshaft position sensors in advancing engine performance.

As automotive technology continues to evolve, the synergy between crankshaft position sensors and engine management systems becomes increasingly critical. The intricate dance of data exchange between these sensors and ECUs underscores their significance in shaping the efficiency, performance, and environmental impact of modern vehicles. In the subsequent section, we will explore best practices for maintaining and ensuring the longevity of crankshaft position sensors, safeguarding their vital role in engine management systems.

Maintenance and Replacement

Regular Inspection and Testing of Crankshaft Position Sensors

To ensure the continued functionality of crankshaft position sensors, regular inspection and testing are essential components of vehicle maintenance. Here are some recommended practices:

- Visual Inspection:

Regularly inspect the sensor and its wiring for signs of wear, damage, or corrosion. Address any visible issues promptly to prevent further damage. - Diagnostic Scans:

Use an OBD-II scanner for periodic diagnostic scans to check for any stored trouble codes related to the crankshaft position sensor. Early detection of issues can prevent potential breakdowns. - Multimeter Testing:

Periodically measure the electrical resistance of the sensor using a multimeter. Compare the readings with the manufacturer’s specifications to ensure the sensor is within the acceptable range. - Road Testing:

During road tests, pay attention to the vehicle’s performance. Any signs of irregular engine behavior, such as stalling, poor acceleration, or difficulty starting, may indicate a potential issue with the crankshaft position sensor.

Signs Indicating the Need for Sensor Replacement

Recognizing the early signs of crankshaft position sensor issues can prevent more severe problems and potential engine damage. Look out for the following indicators that may suggest the need for sensor replacement:

- Check Engine Light (CEL):

If the Check Engine Light illuminates on the dashboard, it could signal a problem with the crankshaft position sensor. Diagnose the issue promptly to avoid complications. - Starting Issues:

Difficulty starting the engine or prolonged cranking times may indicate a malfunctioning crankshaft position sensor. Addressing this promptly can prevent complete engine failure. - Engine Stalling:

If the engine stalls frequently, especially during acceleration or at high speeds, it may be a result of inaccurate data from the crankshaft position sensor. Prompt replacement can restore normal engine operation. - Poor Performance:

Reduced engine performance, manifested as sluggish acceleration or a noticeable decrease in power, can be indicative of sensor issues. Replacement can help restore optimal performance.

DIY vs. Professional Replacement Considerations

Deciding whether to replace the crankshaft position sensor as a DIY project or seeking professional assistance depends on factors such as your technical expertise, access to tools, and the complexity of the replacement process.

DIY Replacement

If you have experience with automotive repairs and access to the necessary tools, replacing the crankshaft position sensor can be a manageable DIY task. Ensure you follow manufacturer guidelines, disconnect the battery before starting, and take necessary safety precautions.

Professional Replacement

If you are not confident in your ability to replace the sensor or if the replacement involves intricate procedures, it’s advisable to seek professional help. Automotive technicians have the expertise and tools to perform the replacement accurately, reducing the risk of errors.

In conclusion, proactive maintenance, regular inspections, and timely replacement of a faulty crankshaft position sensor are essential for preserving the efficiency and reliability of your vehicle’s engine management system. Whether you choose a DIY approach or enlist professional help, addressing sensor issues promptly will contribute to the long-term health of your vehicle.

Case Studies

Real-World Examples of Engine Issues Resolved by Addressing Crankshaft Position Sensor Problems

- Case Study 1: Engine Stalling

Issue: A vehicle consistently experienced sudden engine stalls, especially during acceleration. The Check Engine Light illuminated intermittently.

Resolution: After diagnosing the issue, it was found that the crankshaft position sensor was providing erratic signals. Replacing the sensor restored accurate data transmission, resolving the stalling issue and preventing potential engine damage. - Case Study 2: Poor Acceleration

Issue: A car exhibited sluggish acceleration and a noticeable decrease in power, affecting overall performance.

Resolution: Investigation revealed a failing crankshaft position sensor. Replacing the sensor allowed the Engine Control Module to regain precise control over ignition timing, resulting in improved acceleration and restored engine performance. - Case Study 3: Starting Problems

Issue: A vehicle experienced difficulty starting, with extended cranking times and occasional failure to start.

Resolution: Upon inspection, a faulty crankshaft position sensor was identified. Replacing the sensor resolved the starting issues, ensuring reliable engine ignition and preventing potential breakdowns.

Positive Impacts on Vehicle Performance and Longevity

Addressing crankshaft position sensor problems has consistently shown positive impacts on vehicle performance and longevity. These include:

- Optimized Engine Timing:

Correcting sensor issues ensures accurate engine timing, leading to efficient combustion, improved fuel efficiency, and enhanced power delivery. - Enhanced Fuel Economy:

Properly functioning sensors contribute to optimal fuel injection timing, promoting fuel efficiency and reducing overall fuel consumption. - Reduced Emissions:

Accurate sensor data leads to cleaner combustion, resulting in reduced emissions and compliance with environmental standards. - Prevention of Engine Damage:

Timely replacement of faulty sensors prevents potential engine misfires, stalls, and other issues, safeguarding the engine from long-term damage. - Extended Component Lifespan:

Maintaining a healthy crankshaft position sensor contributes to the prolonged lifespan of associated engine components, such as the catalytic converter and spark plugs.

Future Developments in Crankshaft Position Sensor Technology

Emerging Sensor Technologies

- Advanced Materials:

Research is ongoing to develop sensors using advanced materials that enhance durability, accuracy, and resistance to environmental factors. - Wireless Sensor Networks:

Future crankshaft position sensors may leverage wireless technology, enabling seamless communication with the Engine Control Module without the need for physical wiring.

Integration with Autonomous and Electric Vehicles

- Autonomous Vehicles:

Crankshaft position sensors will play a crucial role in autonomous vehicles, ensuring precise engine control as these vehicles navigate diverse driving scenarios. - Electric Vehicles (EVs):

While traditional crankshaft position sensors may have a reduced role in fully electric vehicles, sensor technologies will evolve to monitor and optimize the performance of electric drivetrains and associated components.

Potential Advancements in Reliability and Accuracy

- Enhanced Sensor Calibration:

Ongoing advancements in calibration techniques aim to improve the accuracy and reliability of crankshaft position sensors, particularly in challenging operating conditions. - Integrated Sensor Systems:

Future developments may involve integrating crankshaft position sensors with other sensors in a holistic engine monitoring system, providing comprehensive data for more refined engine control.

As automotive technology continues to evolve, crankshaft position sensors will undergo advancements to meet the demands of emerging vehicle technologies, contributing to increased efficiency, reliability, and performance. Stay tuned for innovations that will shape the future of engine management systems.

Conclusion

Recap of the Key Role Played by Crankshaft Position Sensors

In summary, crankshaft position sensors emerge as indispensable components in the intricate symphony of modern automotive engineering. These sensors play a pivotal role in ensuring precise engine timing, optimal combustion, and efficient performance. By constantly monitoring the position of the crankshaft, they provide critical data to the Engine Control Module, allowing real-time adjustments that contribute to enhanced fuel efficiency, reduced emissions, and overall vehicle reliability.

Emphasis on the Importance of Regular Maintenance and Prompt Replacement

The vitality of crankshaft position sensors cannot be overstated, and their proper functioning is paramount for the longevity and efficiency of your vehicle. Regular maintenance practices, including visual inspections, diagnostic scans, and testing, are essential for early detection of potential issues. Addressing problems promptly, and considering timely replacement when necessary, safeguards against engine misfires, stalls, and other performance issues, contributing to a smoother and more reliable driving experience.

Closing Thoughts on the Evolving Landscape of Automotive Sensor Technology

As we bid adieu, it’s crucial to acknowledge the dynamic nature of automotive sensor technology. The evolution of crankshaft position sensors reflects the broader trajectory of innovation in the automotive industry. From emerging materials to wireless connectivity and integration with autonomous and electric vehicles, the future promises continued advancements that will reshape how vehicles operate, ensuring they are more efficient, environmentally friendly, and technologically sophisticated.

In this ever-evolving landscape, staying informed about the latest developments in sensor technology and embracing proactive maintenance practices will empower vehicle owners to navigate the road ahead with confidence. Whether you are troubleshooting issues, performing routine inspections, or embracing the latest advancements, the journey of automotive technology promises an exciting and transformative ride. Safe travels!