Coolant Temperature Sensor : Working, Location, Symptoms, Troubleshooting

Automobiles are intricate machines, and various components work together to ensure their optimal performance. One crucial element in this system is the Coolant Temperature Sensor. In this article, we will delve into the definition of the Coolant Temperature Sensor, the importance of maintaining the right engine temperature, and the pivotal role played by Coolant Temperature Sensors in enhancing overall vehicle performance.

Definition of Coolant Temperature Sensors

The Coolant Temperature Sensor, also known as the Engine Coolant Temperature (ECT) sensor, is a vital component in modern vehicles. This sensor is responsible for monitoring the temperature of the engine coolant, ensuring that it remains within the optimal operating range. The ECT sensor typically works in collaboration with the engine control module (ECM) to maintain the right temperature for efficient engine performance.

Importance of Engine Temperature Regulation

Maintaining the proper operating temperature is crucial for the efficient functioning of an internal combustion engine. The engine produces a significant amount of heat during operation, and if not properly regulated, it can lead to various issues such as reduced fuel efficiency, increased emissions, and potential damage to engine components. The Coolant Temperature Sensor plays a key role in preventing these problems by continuously monitoring and regulating the engine temperature.

Role of Coolant Temperature Sensors in Vehicle Performance

Coolant Temperature Sensors contribute significantly to overall vehicle performance. By ensuring the engine operates within the ideal temperature range, these sensors help optimize combustion efficiency, enhance fuel economy, and minimize harmful emissions. Additionally, they play a vital role in the proper functioning of other engine management systems, including ignition timing, fuel injection, and emission control.

In the subsequent sections, we will explore the workings of Coolant Temperature Sensors in greater detail, their types, common issues, and the importance of regular maintenance to ensure their optimal performance. Stay tuned to gain a comprehensive understanding of this critical component and its impact on the longevity and efficiency of your vehicle.

Understanding Coolant Temperature Sensors

Coolant Temperature Sensors employ advanced technology to monitor and regulate engine temperature. This section will explore the operating principles, placement in the engine, and the different types of Coolant Temperature Sensors.

Operating Principles

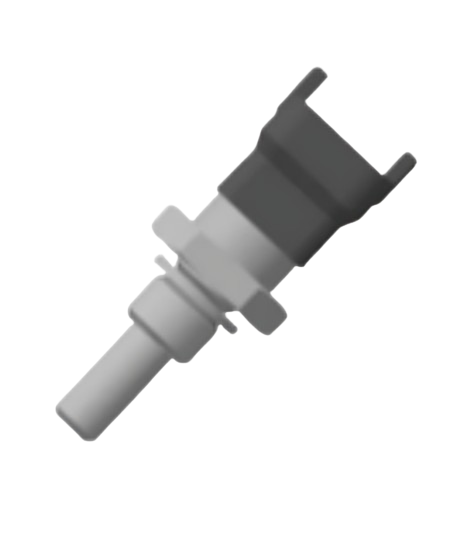

- Thermistor Technology:

Coolant Temperature Sensors primarily utilize thermistor technology. A thermistor is a type of resistor whose electrical resistance varies with temperature. In the case of Coolant Temperature Sensors, a thermistor is embedded in the sensor. As the engine temperature changes, the resistance of the thermistor also changes, providing a crucial parameter for the ECT sensor to determine the coolant temperature accurately. - Resistance and Voltage Relationship:

Understanding the resistance and voltage relationship is fundamental to comprehending how Coolant Temperature Sensors operate. As the engine temperature increases, the resistance of the thermistor decreases. This change in resistance leads to a corresponding change in voltage. The ECT sensor interprets these voltage variations and relays the information to the engine control module, allowing it to make real-time adjustments for optimal engine performance.

Placement in the Engine

Coolant Temperature Sensors are strategically placed within the engine to ensure accurate temperature readings. Typically, they are located near the engine’s coolant passages or in the thermostat housing. This strategic placement enables them to directly monitor the temperature of the coolant circulating through the engine, providing precise data for effective temperature regulation.

Types of Coolant Temperature Sensors

- Negative Temperature Coefficient (NTC) Sensors:

NTC sensors are the most common type used in Coolant Temperature Sensors. As the temperature increases, the electrical resistance of the thermistor decreases. This inverse relationship allows for accurate temperature monitoring in a wide range of operating conditions. - Positive Temperature Coefficient (PTC) Sensors:

PTC sensors, on the other hand, exhibit an increase in resistance with rising temperature. Although less common in automotive applications, they offer unique advantages in certain scenarios. PTC sensors are known for their stability and are often used in specific temperature-sensitive applications.

In the upcoming sections, we will delve deeper into the functionalities and applications of NTC and PTC Coolant Temperature Sensors, providing a comprehensive understanding of their role in maintaining optimal engine temperatures and overall vehicle performance.

The Functionality of Coolant Temperature Sensors

Understanding how Coolant Temperature Sensors function is essential to grasp their impact on various aspects of engine performance. In this section, we will explore the key functionalities of these sensors.

Monitoring Engine Temperature

Coolant Temperature Sensors are primarily tasked with monitoring the temperature of the engine coolant. As the engine operates, the sensor continuously measures the coolant temperature, providing real-time data to the engine control unit (ECU). This constant monitoring ensures that the engine temperature remains within the optimal range for efficient performance.

Transmission of Data to Engine Control Unit (ECU)

The data collected by the Coolant Temperature Sensor is transmitted to the Engine Control Unit (ECU). The ECU, also known as the engine control module, uses this information to make critical decisions related to engine management. Based on the coolant temperature, the ECU can adjust factors such as ignition timing, air-fuel mixture, and idle speed to optimize engine performance under varying operating conditions.

Impact on Fuel Injection and Combustion

One of the key areas influenced by Coolant Temperature Sensors is the fuel injection system. The ECU uses the coolant temperature data to determine the ideal fuel injection timing and duration. In colder temperatures, for instance, the ECU might increase fuel injection to ensure smooth engine startup and operation. Conversely, in warmer conditions, fuel injection may be adjusted to prevent issues such as engine knocking and excessive emissions.

Additionally, Coolant Temperature Sensors play a crucial role in optimizing the combustion process. The sensor’s data allows the ECU to fine-tune the air-fuel mixture, ensuring efficient combustion and maximizing fuel efficiency. This precision in fuel delivery contributes to improved engine performance and reduced environmental impact.

Contribution to Emissions Control

Coolant Temperature Sensors are integral to emissions control in modern vehicles. By providing accurate temperature data to the ECU, these sensors help in regulating the catalytic converter’s efficiency. The ECU can adjust the engine parameters to ensure that the catalytic converter operates optimally, reducing harmful emissions and meeting stringent environmental standards.

In the following sections, we will delve into specific scenarios where Coolant Temperature Sensors play a critical role, such as during engine startup, warm-up phases, and their contribution to overall vehicle efficiency and environmental sustainability. Stay tuned for a comprehensive exploration of the multifaceted role of Coolant Temperature Sensors in the automotive ecosystem.

Symptoms of a Malfunctioning Coolant Temperature Sensor

A malfunctioning Coolant Temperature Sensor can lead to various issues that affect both engine performance and overall vehicle health. In this section, we’ll explore the key symptoms that indicate a problem with the sensor.

Engine Overheating

One of the primary indicators of a malfunctioning Coolant Temperature Sensor is engine overheating. If the sensor fails to accurately measure the coolant temperature, the ECU may not receive the correct data to regulate the engine’s temperature. This can result in insufficient cooling, leading to overheating and potential damage to engine components.

Poor Fuel Efficiency

A faulty Coolant Temperature Sensor can adversely impact fuel efficiency. Incorrect temperature readings may cause the ECU to miscalculate the fuel injection timing and duration, leading to an inefficient air-fuel mixture. This can result in poor fuel combustion, reduced mileage, and increased fuel consumption.

Incorrect Temperature Readings

An unreliable Coolant Temperature Sensor may provide incorrect temperature readings to the ECU. This misinformation can lead to inaccurate adjustments in engine parameters, affecting overall performance. It’s crucial to address any discrepancies in temperature readings promptly to prevent further issues.

Potential Engine Damage

If a malfunctioning Coolant Temperature Sensor goes unnoticed or unaddressed, it can potentially lead to severe engine damage. Consistently operating the engine at incorrect temperatures due to sensor issues can cause premature wear and tear on engine components, reducing the engine’s overall lifespan.

Importance of Regular Maintenance

Maintaining the health of the Coolant Temperature Sensor is essential for the longevity and efficient performance of the vehicle. This section will cover the significance of regular maintenance and the steps involved in ensuring the proper functioning of the sensor.

Periodic Checking and Calibration

Regularly checking and calibrating the Coolant Temperature Sensor is crucial. Periodic inspections can identify potential issues before they escalate. Calibration ensures that the sensor provides accurate temperature readings, allowing the ECU to make precise adjustments for optimal engine performance.

Cleaning and Inspection Procedures

Dust, debris, and coolant residue can accumulate on the sensor over time, affecting its accuracy. Cleaning the sensor and inspecting it for any signs of damage should be a part of routine maintenance. Regular cleaning helps ensure the sensor’s responsiveness and reliability.

Replacing Coolant Temperature Sensors

In cases where the Coolant Temperature Sensor shows signs of malfunction or damage, timely replacement is imperative. Installing a new sensor ensures accurate temperature readings, preventing potential issues such as engine overheating, poor fuel efficiency, and damage to engine components.

By prioritizing regular maintenance and promptly addressing any issues with the Coolant Temperature Sensor, vehicle owners can optimize engine performance, enhance fuel efficiency, and extend the overall lifespan of their vehicles. Stay tuned for insights into best practices for maintaining and troubleshooting Coolant Temperature Sensors in the concluding sections of this article.

Coolant Temperature Sensors in Modern Vehicles

Modern vehicles leverage advanced technologies to enhance performance and efficiency, and Coolant Temperature Sensors are no exception. In this section, we’ll explore the integration of Coolant Temperature Sensors with onboard diagnostics, advancements in sensor technology, and their overall contribution to enhanced vehicle performance.

Integration with Onboard Diagnostics (OBD) Systems

Coolant Temperature Sensors are seamlessly integrated into the vehicle’s Onboard Diagnostics (OBD) system. This integration allows for continuous monitoring of the sensor’s performance and facilitates the detection of any anomalies. OBD systems can generate error codes that help mechanics and technicians identify and address Coolant Temperature Sensor issues during diagnostics.

Advancements in Sensor Technology

Advancements in sensor technology have played a pivotal role in improving the accuracy and reliability of Coolant Temperature Sensors. Modern sensors utilize state-of-the-art materials and manufacturing techniques, resulting in enhanced durability and precision. These advancements contribute to more efficient temperature monitoring and regulation, promoting overall engine health.

Enhanced Performance and Efficiency

The integration of advanced Coolant Temperature Sensors contributes to the enhanced performance and efficiency of modern vehicles. Accurate temperature readings allow the ECU to make rapid and precise adjustments, optimizing fuel injection, ignition timing, and other critical engine parameters. This level of control leads to improved fuel efficiency, reduced emissions, and overall better driving experiences for vehicle owners.

How to Troubleshooting and Diagnosis Coolant Temperature Sensor

Even with advancements in technology, Coolant Temperature Sensors can experience issues. This section will cover the troubleshooting and diagnosis processes, including the use of diagnostic tools, common problems, and effective solutions.

Using Diagnostic Tools

Diagnostic tools play a crucial role in troubleshooting Coolant Temperature Sensor issues. OBD scanners can retrieve error codes from the vehicle’s computer, providing insights into specific problems related to the sensor. Mechanics and technicians use these tools to analyze data, identify malfunctions, and initiate targeted repairs.

Common Coolant Temperature Sensor Issues

Common issues with Coolant Temperature Sensors include sensor malfunctions, wiring problems, and connectivity issues. Sensor malfunctions can lead to inaccurate temperature readings, while wiring problems may result in intermittent signal transmission. Addressing these issues promptly is essential to prevent adverse effects on engine performance.

Addressing Malfunctions Effectively

Effective troubleshooting involves a systematic approach to address Coolant Temperature Sensor malfunctions. This includes inspecting sensor connections, testing sensor resistance, and verifying wiring integrity. In cases of irreparable damage or malfunction, replacing the Coolant Temperature Sensor with a new, reliable unit is the recommended solution.

By staying informed about the integration of Coolant Temperature Sensors in modern vehicles, utilizing diagnostic tools for efficient troubleshooting, and addressing issues promptly, vehicle owners and technicians can ensure the continued optimal performance of these crucial components. The combination of advanced technology and effective maintenance practices contributes to a smoother and more reliable driving experience in contemporary automobiles.

Conclusion

In conclusion, the Coolant Temperature Sensor stands as a critical component in the intricate machinery of modern vehicles, playing a pivotal role in maintaining optimal engine temperature and ensuring efficient performance.

Recap of Coolant Temperature Sensor’s Role

We began by defining the Coolant Temperature Sensor and understanding its significance in monitoring engine temperature. The sensor’s ability to provide real-time data to the Engine Control Unit (ECU) facilitates precise adjustments in various engine parameters, influencing fuel injection, combustion efficiency, and emissions control.

Emphasizing the Importance of Regular Maintenance

We then delved into the symptoms of a malfunctioning Coolant Temperature Sensor, highlighting the potential repercussions such as engine overheating, poor fuel efficiency, and the risk of engine damage. The importance of regular maintenance, including periodic checks, calibration, and cleaning, emerged as a key theme to ensure the proper functioning of the sensor.

Future Trends and Innovations in Engine Temperature Regulation

Looking forward, the integration of Coolant Temperature Sensors into modern vehicles is set to evolve further. Integration with Onboard Diagnostics (OBD) systems and continuous advancements in sensor technology contribute to enhanced performance and efficiency. We touched upon the exciting possibilities of future trends and innovations in engine temperature regulation, paving the way for even more sophisticated and responsive automotive systems.

FAQ

Q: How do I know if my Coolant Temperature Sensor is malfunctioning?

A: Signs of a malfunctioning Coolant Temperature Sensor include engine overheating, poor fuel efficiency, incorrect temperature readings on the dashboard, and potential damage to engine components. If you notice any of these symptoms, it’s advisable to have the sensor checked and, if necessary, replaced.

Q: Can a malfunctioning Coolant Temperature Sensor cause long-term damage to my engine?

A: Yes, a malfunctioning Coolant Temperature Sensor can potentially lead to long-term damage. If the engine operates at incorrect temperatures for extended periods, it may result in premature wear and tear on various components, reducing the overall lifespan of the engine.

Q: How often should I have my Coolant Temperature Sensor checked?

A: Regular maintenance is crucial. It’s recommended to include Coolant Temperature Sensor checks during routine vehicle inspections, especially if you notice any performance issues. Periodic calibration, cleaning, and inspection can help ensure the sensor’s accuracy and reliability.

Q: Can I drive my vehicle with a malfunctioning Coolant Temperature Sensor?

A: While it may be possible to drive with a malfunctioning sensor for a short period, it’s not advisable in the long run. Ignoring Coolant Temperature Sensor issues can lead to engine damage, reduced fuel efficiency, and increased emissions. It’s best to address sensor problems promptly to avoid further complications.

Q: Are there different types of Coolant Temperature Sensors, and do they perform differently?

A: Yes, there are different types of Coolant Temperature Sensors, with Negative Temperature Coefficient (NTC) and Positive Temperature Coefficient (PTC) sensors being the two main categories. NTC sensors are more common and exhibit a decrease in resistance with increasing temperature, while PTC sensors show the opposite behavior. The choice of sensor type depends on the specific requirements of the vehicle’s engine management system