The Role of Engine Management Systems (EMS) : Optimizing Power and Efficiency

In the rapidly advancing realm of automotive technology, Engine Management Systems (EMS) play a pivotal role in ensuring optimal performance and efficiency of modern vehicles. As we delve into the intricacies of EMS, it becomes evident that these systems are more than just a mechanical component; they are the brains behind the brawn, orchestrating a symphony of functions to keep our vehicles running smoothly.

Definition of Engine Management Systems (EMS)

Engine Management Systems, commonly abbreviated as EMS, refer to a sophisticated network of electronic controls designed to oversee and regulate the various aspects of an internal combustion engine. These systems utilize a combination of sensors, actuators, and a central processing unit to monitor and manage critical functions, ensuring the engine operates at peak efficiency.

Importance of EMS in Modern Vehicles

In the contemporary automotive landscape, the importance of Engine Management Systems cannot be overstated. These systems have evolved to become the nerve center of a vehicle’s powertrain, responsible for optimizing fuel efficiency, controlling emissions, and enhancing overall performance. EMS technology enables vehicles to adapt to varying driving conditions, providing a seamless and dynamic driving experience.

Evolution of EMS Technology

The evolution of EMS technology has been a fascinating journey, marked by constant innovation and adaptation. From the early days of basic engine control modules to the sophisticated and interconnected systems of today, EMS has undergone a remarkable transformation. The integration of advanced sensors, real-time data processing, and machine learning has propelled EMS into a new era, where precision and efficiency are paramount.

As we progress further into this discussion, we will explore the intricate components of EMS, the role they play in enhancing engine performance, and the future trends that are set to shape the landscape of engine management in the automotive industry.

What is the full form of EMS

In the automotive industry, EMS stands for “Engine Management System.”

Key Components of Engine Management Systems

As we navigate the intricate landscape of Engine Management Systems (EMS), understanding the key components becomes paramount. Each element plays a crucial role in orchestrating the symphony of functions that ensure an internal combustion engine operates with precision and efficiency.

What is The Engine Control Unit (ECU)

- Role and Functions At the heart of every Engine Management System lies the Engine Control Unit (ECU). This electronic brain serves as the command center, processing real-time data from various sensors and making critical decisions to optimize engine performance. The ECU interprets inputs and adjusts parameters such as fuel injection, ignition timing, and airflow to maintain an optimal balance between power, efficiency, and emissions.

- Importance in Optimizing Performance The ECU’s ability to adapt to changing driving conditions and optimize performance is unparalleled. By constantly analyzing sensor data, the ECU can fine-tune the engine’s operation, ensuring it operates at peak efficiency under diverse scenarios. This adaptability is crucial not only for enhancing power output but also for achieving fuel efficiency and emission control.

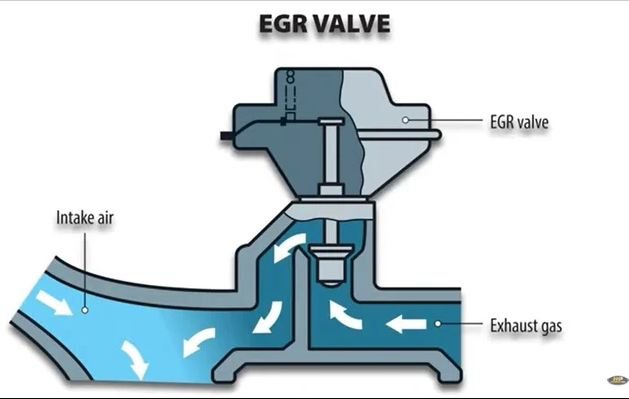

Sensors

- Types of Sensors Used in EMS Engine Management Systems employ an array of sensors, each specializing in monitoring specific parameters. Common types include:

- Mass Air Flow (MAF) sensors

- Throttle Position Sensors (TPS)

- Oxygen Sensors (O2)

- Engine Coolant Temperature Sensors (ECT)

- Crankshaft Position Sensors (CKP)

- Camshaft Position Sensors (CMP)

- Their Functions in Monitoring and Controlling the Engine Sensors act as the eyes and ears of the EMS, continuously collecting data on factors like air intake, engine temperature, and exhaust composition. This data is crucial for the ECU to make informed decisions regarding fuel injection, ignition timing, and other parameters. The synergy between sensors and the ECU is fundamental in achieving optimal engine performance.

Actuators

- Components Responsible for Executing Control Decisions Actuators in EMS are the hands and feet, translating the ECU’s decisions into tangible actions. Key components include:

- Fuel Injectors: Dispense precise amounts of fuel into the combustion chambers.

- Ignition Coils: Control the timing and intensity of spark ignition.

- Throttle Actuators: Regulate the airflow into the engine.

- Idle Air Control Valves: Manage idle speed by adjusting air intake.

- Examples and Their Roles in EMS Actuators work in harmony to implement the ECU’s directives, influencing combustion, air-fuel mixture, and overall engine dynamics. For instance, fuel injectors ensure accurate fuel delivery, while ignition coils determine the ignition timing, contributing to the engine’s overall efficiency and power output.

Understanding these key components sheds light on the intricate dance between electronic control, sensory input, and mechanical execution within Engine Management Systems. In the next section, we’ll explore how these components collaborate to achieve the optimal functioning of an internal combustion engine.

Functions of Engine Management Systems

As we delve deeper into the intricate functions of Engine Management Systems (EMS), it becomes evident that these systems are the architects of precision in the realm of internal combustion engines. The seamless coordination of various functions is what allows modern vehicles to achieve optimal performance, efficiency, and emission control.

Fuel Injection

- Importance of Precise Fuel Delivery Fuel injection, a cornerstone function of EMS, is the process of delivering the right amount of fuel to the combustion chambers at precisely the right moment. The significance lies in achieving the perfect air-fuel mixture for combustion. Precision in fuel delivery is crucial for maximizing power output, ensuring smooth engine operation, and minimizing fuel wastage.

- Impact on Fuel Efficiency and Emissions The accuracy of fuel injection directly influences fuel efficiency. When the engine receives the ideal fuel quantity, combustion is more efficient, resulting in better fuel mileage. Additionally, precise fuel delivery contributes to lower emissions, as it minimizes unburned fuel and reduces the environmental footprint of the vehicle.

Ignition Timing

- Role in Optimizing Combustion Ignition timing is the precise moment when the spark plug ignites the air-fuel mixture in the combustion chamber. EMS constantly adjusts this timing to optimize combustion. Proper ignition timing ensures that the maximum pressure is applied to the piston at the right point in its stroke, maximizing power output while minimizing stress on the engine components.

- Influence on Engine Performance The impact of ignition timing on engine performance is profound. When the spark occurs at the right time, it contributes to smooth acceleration, reduced knocking, and improved overall engine responsiveness. EMS’s ability to dynamically adjust ignition timing in response to changing conditions ensures optimal performance across various driving scenarios.

Air-Fuel Ratio Control

- Maintaining the Ideal Mixture for Combustion Achieving the ideal air-fuel mixture is a delicate balance that EMS meticulously manages. The air-fuel ratio, representing the quantity of air compared to fuel in the combustion chamber, significantly influences combustion efficiency. EMS adjusts this ratio in real-time to adapt to different driving conditions, ensuring the engine operates at its most efficient state.

- Implications for Efficiency and Emissions The control of the air-fuel ratio by EMS not only enhances efficiency but also has direct implications for emissions control. A well-maintained air-fuel ratio promotes complete combustion, minimizing the release of pollutants. This meticulous control is vital in meeting stringent emission standards and reducing the environmental impact of vehicular emissions.

In this section, we’ve explored the fundamental functions of EMS, focusing on fuel injection, ignition timing, and air-fuel ratio control. The synergy of these functions illustrates the intricate dance of precision that EMS orchestrates, defining the performance and environmental impact of modern internal combustion engines.

Advanced Features of Engine Management Systems

As technology continues to advance, Engine Management Systems (EMS) evolve to incorporate sophisticated features that push the boundaries of performance and efficiency in internal combustion engines. In this section, we explore advanced functionalities that exemplify the adaptability and innovation embedded in modern EMS.

Adaptive Learning

- How EMS Adapts to Driving Conditions Adaptive Learning is a revolutionary feature in EMS, enabling the system to continuously learn and adapt to the driver’s habits and prevailing driving conditions. Through real-time analysis of data from various sensors, the EMS adjusts parameters such as fuel injection timing, air-fuel ratio, and ignition timing to optimize performance based on the driver’s preferences and the environment.

- Benefits for Long-term Performance The adaptive learning capability ensures that the engine operates at its best under diverse circumstances. Over time, this not only enhances immediate performance but also contributes to long-term durability and efficiency. The adaptability to driving styles and conditions positions the vehicle for optimal performance throughout its lifespan.

Turbocharger and Supercharger Control

- Optimizing Forced Induction for Power Turbochargers and superchargers are integral components for enhancing engine power through forced induction. EMS plays a pivotal role in controlling these devices, managing boost levels and ensuring the optimal delivery of compressed air to the engine. This leads to increased power output without a proportional increase in engine size.

- Challenges and Solutions in EMS Controlling forced induction presents challenges such as turbo lag and managing the additional stress on engine components. EMS addresses these challenges by precisely regulating the speed and pressure of the turbocharger or supercharger. By synchronizing the forced induction with engine demands, EMS mitigates lag and optimizes power delivery, striking a delicate balance between performance and reliability.

Variable Valve Timing (VVT)

- Improving Efficiency Through Dynamic Valve Control Variable Valve Timing (VVT) is a breakthrough in engine technology that optimizes efficiency by adjusting the timing of the opening and closing of the engine’s valves. EMS dynamically controls VVT, allowing for changes in valve timing based on engine speed, load, and driving conditions. This results in improved combustion efficiency and power delivery across the entire RPM range.

- Role of EMS in VVT Implementation The implementation of VVT requires precise coordination between the EMS and the engine’s mechanical components. EMS monitors data from sensors and uses this information to adjust the timing of the camshaft, altering the opening and closing of valves. This dynamic control ensures that the engine operates with maximum efficiency, delivering both power and fuel economy.

In this section, we’ve explored advanced features of Engine Management Systems, including adaptive learning, turbocharger and supercharger control, and Variable Valve Timing (VVT). These innovations showcase the adaptability and intelligence of modern EMS, pushing the boundaries of performance in internal combustion engines.

Challenges and Solutions in Engine Management Systems

Engine Management Systems (EMS) have undoubtedly revolutionized the automotive industry, but they are not without challenges. Addressing these challenges is crucial to ensuring the reliability, performance, and adaptability of these intricate electronic systems.

Reliability and Durability

- Ensuring Longevity in Complex Electronic Systems The complexity of EMS, with its numerous electronic components and intricate interconnections, poses challenges to reliability and durability. Electronic systems are susceptible to environmental factors, such as temperature variations and moisture, which can affect their performance over time. Ensuring the longevity of EMS requires rigorous testing, quality components, and continuous advancements in materials and manufacturing processes.

- Redundancy and Fail-safes To mitigate the risks associated with electronic failures, modern EMS incorporates redundancy and fail-safe mechanisms. Redundancy involves duplicating critical components, ensuring that if one fails, the backup can seamlessly take over. Fail-safes involve programming the EMS to detect abnormalities and, if necessary, revert to predefined safe operating parameters. These measures enhance the reliability of EMS, even in challenging conditions.

Performance Tuning and Customization

- Aftermarket Modifications and Their Impact on EMS The growing trend of aftermarket modifications poses challenges for EMS. When vehicle owners make changes to components such as air intake systems, exhausts, or even engine internals, the EMS may not be optimized for these alterations. This can lead to issues such as poor performance, increased emissions, or even potential damage to the engine.

- Balancing Performance and Reliability Achieving the delicate balance between enhanced performance and maintaining reliability is a perpetual challenge. EMS must be versatile enough to accommodate aftermarket modifications while ensuring that the engine operates within safe parameters. Striking this balance often requires sophisticated tuning and calibration, considering factors like air-fuel ratios, ignition timing, and sensor inputs.

In conclusion, while Engine Management Systems have ushered in a new era of efficiency and performance in the automotive world, they are not exempt from challenges. Addressing issues related to reliability, durability, and the impact of aftermarket modifications is crucial for ensuring that EMS continues to be a driving force in optimizing internal combustion engines for the future.

VI. Future Trends in Engine Management Systems

The evolution of Engine Management Systems (EMS) continues as the automotive industry strives for greater efficiency, reduced emissions, and improved performance. Future trends in EMS point towards integration with cutting-edge technologies and the adaptation to emerging powertrain solutions.

A. Integration with AI and Machine Learning

- Enhancing Adaptability and Optimization The integration of Artificial Intelligence (AI) and Machine Learning (ML) into EMS heralds a new era of adaptability and optimization. AI algorithms can process vast amounts of data in real-time, allowing EMS to learn and adapt to driving conditions with unprecedented precision. This enables continuous refinement of engine parameters for optimal performance, fuel efficiency, and emissions control.

- Potential Advancements in Autonomous Driving As autonomous driving technologies advance, EMS will play a pivotal role in seamlessly integrating engine management with the requirements of self-driving vehicles. AI-driven EMS can anticipate the vehicle’s power needs, adapting in real-time to ensure a harmonious balance between energy efficiency and performance, contributing to the evolution of autonomous driving systems.

B. Electrification and Hybrid Systems

- Adapting EMS to Hybrid Powertrains With the rise of electrification, EMS is undergoing significant adaptations to accommodate hybrid powertrains. Hybrid systems, combining internal combustion engines with electric propulsion, require EMS to manage power delivery from both sources efficiently. This involves coordinating the combustion engine, electric motor, and energy storage systems to optimize overall vehicle performance.

- Challenges and Opportunities in Electrified Vehicle EMS Electrified vehicle EMS faces challenges such as managing complex power distribution and optimizing energy regeneration during braking. However, it also presents opportunities for improving energy efficiency and reducing overall emissions. Advanced EMS in electrified vehicles can enhance the driving experience by seamlessly transitioning between electric and combustion modes.

Conclusion

Recap of the Importance of Engine Management Systems

In conclusion, Engine Management Systems remain the linchpin of automotive performance and efficiency. From the foundational functions of fuel injection and ignition timing to the integration of advanced features like adaptive learning and electrification, EMS continues to be a driving force in optimizing internal combustion engines.

Anticipated Developments and Innovations in EMS

Anticipated developments in EMS include even greater integration with AI and machine learning, providing unprecedented adaptability and optimization. The growing trend towards electrification and hybrid systems will see EMS evolving to meet the demands of diverse powertrain configurations, contributing to cleaner and more efficient transportation.

Final Thoughts on the Role of EMS in the Automotive Industry

As we look to the future, the role of Engine Management Systems in the automotive industry is poised to become even more critical. EMS will be instrumental in achieving the delicate balance between performance, efficiency, and environmental responsibility. The continuous innovation and adaptation of EMS showcase its resilience and versatility, ensuring its relevance in shaping the future of transportation.

Decoding the Mystery: Understanding and Fixing P0440 OBD-II Fault Code - Faults Code

23rd Feb 2024[…] The Role of Engine Management Systems (EMS) : […]

The Ultimate Guide To Camshaft Position Sensors In 2024 – Faults Code

24th Feb 2024[…] The Role of Engine Management Systems (EMS) : […]