The Ultimate Guide to Camshaft Position Sensors in 2024

Camshaft Position Sensor – Introduction

Automotive systems rely heavily on a multitude of sensors to ensure optimal performance. These sensors play a pivotal role in monitoring and regulating various components, contributing to the overall efficiency and functionality of vehicles. Among these critical sensors, the camshaft position sensor stands out as a key player in engine management. In this article, we’ll delve into the intricate world of automotive sensors, focusing specifically on the importance of the camshaft position sensor and its indispensable role in enhancing engine performance.

Brief Overview of the Role of Sensors in Automotive Systems

Modern vehicles are equipped with an array of sensors that act as the sensory organs, providing real-time data to the vehicle’s onboard computer. These sensors serve diverse functions, ranging from monitoring engine parameters to ensuring the safety and comfort of passengers. The integration of advanced sensor technology has revolutionized the automotive industry, enabling vehicles to operate more efficiently and with heightened precision.

Introduction to the Camshaft Position Sensor

One such sensor that plays a crucial role in engine performance is the camshaft position sensor. Before we delve into its significance, let’s understand the basics. The camshaft position sensor is a vital component of the engine management system, responsible for monitoring the position and speed of the camshaft. This information is relayed to the engine control unit (ECU), allowing it to make real-time adjustments to optimize combustion and overall engine operation.

Importance of the Camshaft Position Sensor in Engine Performance

The camshaft position sensor holds immense importance in ensuring the smooth and efficient operation of an engine. By precisely tracking the position and speed of the camshaft, it enables the ECU to synchronize the fuel injection and ignition timing. This synchronization is critical for achieving optimal combustion efficiency, reducing emissions, and maximizing fuel efficiency.

Furthermore, the camshaft position sensor plays a pivotal role in the functionality of variable valve timing (VVT) systems. VVT systems rely on accurate camshaft position data to adjust the timing of the intake and exhaust valves, optimizing performance at different engine speeds. This dynamic control not only enhances power delivery but also contributes to improved fuel economy.

In the following sections, we will explore the technical aspects of camshaft position sensors, their types, common issues, and maintenance practices. Join us on this informative journey into the heart of automotive technology as we unravel the intricacies of the camshaft position sensor and its impact on engine performance.

Understanding the Camshaft Position Sensor

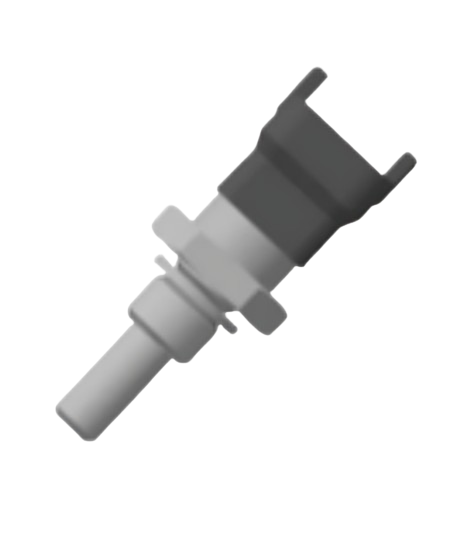

Definition and Purpose

The camshaft position sensor, often abbreviated as CPS, is a vital component within the engine management system. Its primary purpose is to monitor the rotational position and speed of the camshaft. As the camshaft plays a crucial role in controlling the opening and closing of the engine’s valves, the camshaft position sensor provides essential data to the engine control unit (ECU). This data allows the ECU to precisely time the fuel injection and ignition spark, ensuring optimal combustion efficiency and engine performance.

Location Within the Engine

The camshaft position sensor is strategically located to have a direct line of sight to the camshaft’s rotating components. Typically positioned near the camshaft, it may be installed on the cylinder head, engine block, or within the timing cover. The exact location can vary between different engine models and manufacturers. Its placement is critical to ensuring accurate readings of the camshaft’s position and speed.

How the Camshaft Position Sensor Works

Understanding the functioning of the camshaft position sensor requires a closer look at its internal workings. The sensor is often a Hall-effect or a magnetoresistive type, both of which are capable of generating electrical signals based on changes in magnetic fields.

When the camshaft rotates, it features a toothed wheel or a series of notches known as the reluctor. The camshaft position sensor detects the changes in the magnetic field as these teeth or notches pass by. This induces a voltage signal, which is then sent to the ECU. By analyzing the frequency and amplitude of these signals, the ECU can precisely determine the camshaft’s position and speed.

The ECU uses this information to adjust the timing of the fuel injection and ignition spark. In engines equipped with variable valve timing (VVT), the camshaft position sensor’s data is also crucial for optimizing the timing of the intake and exhaust valves.

The camshaft position sensor operates in real-time, providing continuous feedback to the ECU. This dynamic feedback loop enables the engine management system to adapt to changes in driving conditions, ensuring optimal performance, fuel efficiency, and emissions control.

In the next section, we will explore the different types of camshaft position sensors, their variations, and the advancements in sensor technology that have contributed to the efficiency and precision of modern engine management systems. Stay tuned for an in-depth exploration of these intriguing components that lie at the heart of automotive technology.

Significance in Engine Functionality

Role in Synchronization

The camshaft position sensor’s pivotal role in synchronization cannot be overstated. As the camshaft dictates the precise timing of the engine’s valve operations, the sensor ensures that the engine control unit (ECU) receives accurate and real-time information. This synchronization is fundamental to the harmonious operation of the engine, preventing valve and piston interference and optimizing overall performance.

Impact on Fuel Injection Timing

In addition to synchronization, the camshaft position sensor plays a crucial role in determining the timing of fuel injection. By precisely monitoring the camshaft’s position and speed, the sensor enables the ECU to determine the optimal moment to inject fuel into the combustion chamber. This precision in fuel injection timing is essential for achieving efficient combustion, maximizing power output, and minimizing emissions.

Contribution to Overall Engine Efficiency

The cumulative impact of accurate synchronization and precise fuel injection timing contributes significantly to the overall efficiency of the engine. With the camshaft position sensor serving as the eyes and ears of the engine control system, it ensures that combustion processes are finely tuned. This not only enhances power delivery but also promotes fuel economy and reduces harmful emissions, aligning with contemporary automotive industry standards and environmental considerations.

Common Symptoms of Camshaft Position Sensor Issues

Engine Misfires

One of the telltale signs of a malfunctioning camshaft position sensor is engine misfires. When the sensor provides inaccurate or inconsistent data to the ECU, it can lead to misalignment in fuel injection and ignition timing. This misalignment can result in incomplete combustion, causing the engine to misfire and affecting overall performance.

Difficulty in Starting the Engine

A faulty camshaft position sensor can also manifest in difficulty starting the engine. If the sensor fails to provide the ECU with the correct position information, the engine may struggle to start or experience prolonged cranking times. This is a clear indication of a potential issue with the sensor’s functionality.

Decreased Fuel Efficiency

Since the camshaft position sensor plays a key role in optimizing fuel injection timing, a malfunctioning sensor can lead to decreased fuel efficiency. Inaccurate timing can result in inefficient combustion, leading to increased fuel consumption. Monitoring changes in fuel efficiency can help diagnose potential issues with the camshaft position sensor.

In the upcoming sections, we will explore troubleshooting and maintenance practices for camshaft position sensors, providing valuable insights into diagnosing and resolving issues that may arise. Stay tuned for practical tips on ensuring the optimal performance of this critical engine component.

Diagnostic Techniques

Use of OBD-II Scanners

Diagnosing issues related to the camshaft position sensor has been made more accessible with the advent of On-Board Diagnostics II (OBD-II) technology. OBD-II scanners are valuable tools that can connect to the vehicle’s diagnostic port and retrieve error codes stored in the engine control unit (ECU). Specific trouble codes related to the camshaft position sensor, such as P0340 or P0341, can provide crucial insights into potential malfunctions. OBD-II scanners facilitate a quick and efficient initial assessment, guiding technicians toward a more targeted diagnostic approach.

Visual Inspection and Testing Procedures

In addition to electronic diagnostics, a thorough visual inspection and testing procedures are essential for identifying camshaft position sensor issues. Technicians may inspect the sensor for physical damage, wiring issues, or loose connections. Testing the sensor’s electrical continuity and resistance can provide insights into its functionality. Moreover, using specialized tools, such as oscilloscopes, can help analyze the sensor’s output signals and ensure they align with the expected parameters.

Importance of Timely Diagnosis and Replacement

Timely diagnosis and replacement of a faulty camshaft position sensor are crucial to maintaining optimal engine performance. Ignoring or delaying addressing sensor issues can lead to a domino effect, impacting fuel efficiency, emissions, and overall engine functionality. Prompt replacement ensures that the engine management system operates at its best, preventing potential damage to other components and minimizing the risk of more extensive and costly repairs.

Importance in Modern Engine Management Systems

Integration with Electronic Control Units (ECUs)

Camshaft position sensors are integral components of modern engine management systems, seamlessly integrated with electronic control units (ECUs). The real-time data provided by these sensors allows the ECU to make instantaneous adjustments to fuel injection timing, ignition spark, and, in engines with variable valve timing (VVT), valve operation. This level of integration enhances engine responsiveness, efficiency, and overall performance.

Camshaft Position Sensor in Advanced Engine Technologies

As automotive technology advances, so does the role of the camshaft position sensor. In advanced engine technologies, such as direct injection and turbocharging, the precise synchronization provided by the sensor becomes even more critical. These technologies rely on accurate timing for optimal efficiency and power delivery, making the camshaft position sensor a linchpin in the implementation of cutting-edge engine designs.

Role in Meeting Emission Standards

Camshaft position sensors contribute significantly to meeting stringent emission standards. By ensuring precise control over combustion processes, these sensors play a vital role in minimizing emissions of pollutants such as nitrogen oxides (NOx) and hydrocarbons. As environmental regulations become more stringent, the reliability and accuracy of camshaft position sensors become increasingly essential in achieving compliance with emission standards.

In the final section of this comprehensive article, we will explore preventive maintenance practices and offer practical tips for ensuring the longevity and optimal performance of camshaft position sensors. Stay tuned for insights into keeping this critical engine component in top condition.

Camshaft Position Sensor Maintenance

Regular Inspection Intervals

To ensure the longevity and optimal performance of the camshaft position sensor, incorporating regular inspection intervals into the vehicle maintenance schedule is paramount. Scheduled checks, ideally during routine engine servicing, allow technicians to assess the sensor’s condition, identify potential issues, and address them proactively. Implementing a preventive maintenance approach can significantly reduce the risk of unexpected sensor failures and associated engine problems.

Cleaning and Proper Handling

Camshaft position sensors are exposed to the harsh conditions within the engine compartment, and contaminants such as oil, debris, or engine fluids can affect their performance. Regular cleaning with a gentle solvent and a soft brush can help remove accumulated dirt without causing damage. Additionally, proper handling during installation and removal is crucial to prevent physical damage or misalignment. Following manufacturer guidelines for cleaning and handling ensures the sensor remains in optimal condition.

Importance of Using Quality Replacement Parts

When replacement becomes necessary, choosing high-quality, OEM (Original Equipment Manufacturer) or equivalent replacement parts is essential. Quality sensors are engineered to meet specific performance standards and are designed to seamlessly integrate with the vehicle’s engine management system. Using substandard or counterfeit parts may compromise accuracy and reliability, leading to potential engine issues. Investing in quality replacements ensures the continued efficiency of the camshaft position sensor.

Case Studies

Real-World Examples of Engine Issues Related to Camshaft Position Sensor Failure

- Engine Misfires and Reduced Performance: In a case study involving a modern vehicle, the camshaft position sensor failure resulted in persistent engine misfires and a noticeable reduction in overall performance. The inaccurate timing data led to inefficient combustion, impacting power delivery and fuel efficiency.

- Difficulty in Starting: Another case involved a vehicle experiencing difficulty in starting. Upon diagnosis, it was revealed that a faulty camshaft position sensor was sending erratic signals to the ECU, causing prolonged cranking times and intermittent engine stalls.

Outcomes and Solutions Implemented

- Diagnostic and Replacement: In the first case, a thorough diagnostic process using OBD-II scanners and visual inspections pinpointed the camshaft position sensor as the culprit. Following the diagnosis, a quality OEM replacement sensor was installed, restoring proper engine function and eliminating misfires.

- Cleaning and Adjustment: In the second case, a visual inspection revealed contaminants affecting the sensor’s performance. After cleaning and ensuring proper alignment during reinstallation, the difficulties in starting were resolved without the need for a replacement.

These case studies underscore the importance of timely diagnostics and appropriate solutions when dealing with camshaft position sensor issues. Whether through replacement or maintenance, addressing these issues promptly can prevent further damage, ensuring the vehicle operates optimally and meets performance expectations.

In conclusion, a proactive approach to camshaft position sensor maintenance, coupled with effective diagnostic techniques, contributes to the overall health and longevity of the engine. By understanding the significance of these sensors and implementing preventive measures, vehicle owners and technicians alike can enjoy the benefits of reliable engine performance.

Future Trends and Innovations

Advancements in Camshaft Position Sensor Technology

As automotive technology continues to evolve, camshaft position sensor technology is expected to undergo significant advancements. These may include improvements in sensor sensitivity, precision, and durability. Miniaturization and integration with other sensors may enhance overall efficiency and reliability. Advanced materials and manufacturing processes could contribute to sensors that withstand harsh environmental conditions, ensuring consistent performance over extended periods.

Integration with Autonomous and Electric Vehicle Systems

The rise of autonomous and electric vehicles presents new challenges and opportunities for camshaft position sensors. In electric vehicles (EVs), the focus may shift to sensor technologies that monitor critical components beyond traditional combustion engines. In autonomous vehicles, the need for highly accurate and real-time data becomes even more crucial, and camshaft position sensors may evolve to meet the unique demands of autonomous driving systems.

Impact on the Automotive Industry

The evolution of camshaft position sensor technology will undoubtedly have a profound impact on the automotive industry. As vehicles become more connected and technologically advanced, the reliability and performance of critical sensors, including the camshaft position sensor, will play a central role in shaping the future of transportation. This impact extends beyond individual vehicle performance to influencing broader industry trends, regulatory standards, and the development of innovative automotive solutions.

Conclusion

Recap of the Importance of the Camshaft Position Sensor

In conclusion, the camshaft position sensor stands as a linchpin in the intricate machinery of modern engines. Its role in synchronization, fuel injection timing, and overall engine efficiency is indispensable to achieving optimal performance and meeting stringent emission standards. As showcased throughout this article, the camshaft position sensor’s accurate and real-time data is fundamental to the smooth operation of the engine.

Emphasis on Regular Maintenance and Timely Replacements

The longevity and reliability of the camshaft position sensor are contingent on proactive maintenance and timely replacements. Regular inspections, cleaning, and the use of quality replacement parts are essential practices to ensure the sensor functions optimally throughout the lifespan of the vehicle. Ignoring signs of sensor issues or neglecting maintenance can lead to performance degradation, reduced fuel efficiency, and potential engine damage.

Closing Thoughts on the Role of Sensors in the Future of Automotive Technology

Looking ahead, the future of automotive technology holds exciting possibilities, and sensors, including the camshaft position sensor, will continue to be at the forefront of these innovations. The ongoing integration of sensors into advanced vehicle systems, coupled with the development of electric and autonomous technologies, will reshape the landscape of transportation. As we embrace these changes, a keen understanding of the importance of sensors and a commitment to their maintenance will remain pivotal in ensuring the efficiency, reliability, and sustainability of vehicles for years to come.

This comprehensive exploration into the world of camshaft position sensors concludes with the anticipation of a dynamic and technologically-driven future for the automotive industry.