The Role of Rail Pressure Sensors: Unlocking Engine Power

Overview of Rail Pressure Sensors

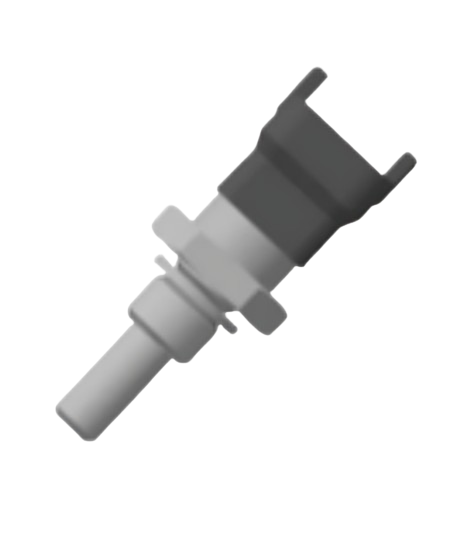

Rail pressure sensors play a pivotal role in the optimal functioning of modern automotive engines. These sensors are designed to measure the fuel pressure within the fuel rail of a vehicle’s engine. By providing real-time data on fuel pressure, rail pressure sensors enable precise fuel delivery, ensuring efficient engine performance.

Importance of Rail Pressure Sensors in Automotive Engines

The significance of rail pressure sensors in automotive engines cannot be overstated. In today’s highly advanced and fuel-efficient engines, maintaining the right fuel pressure is crucial for achieving optimal combustion and maximizing power output while minimizing emissions. Rail pressure sensors serve as the eyes of the engine management system, continuously monitoring fuel pressure and providing feedback to the engine control unit (ECU) for precise fuel injection control.

Thesis Statement: Exploring the significance and functions of rail pressure sensors in modern vehicle engines.

In this article, we will delve into the intricacies of rail pressure sensors, exploring their importance and various functions in modern vehicle engines. From understanding how these sensors work to their role in enhancing engine efficiency and performance, we will uncover the critical role that rail pressure sensors play in the automotive industry.

The Basics of Rail Pressure Sensors

Definition and Function

Rail pressure sensors are essential components in automotive fuel systems designed to measure the pressure of fuel within the fuel rail. The primary function of these sensors is to provide accurate data on fuel pressure to the engine control unit (ECU), allowing for precise fuel injection timing and quantity adjustment.

Types of Rail Pressure Sensors

- Direct Injection Systems: In direct injection systems, rail pressure sensors are integral to the fuel delivery process. They monitor the pressure of fuel directly injected into the combustion chamber, ensuring optimal combustion efficiency.

- Common Rail Systems: Common rail systems utilize rail pressure sensors to regulate fuel pressure in a common rail that supplies fuel to multiple injectors. These sensors help maintain consistent fuel pressure across all injectors, resulting in improved engine performance and emissions control.

Components and Working Principle

- Sensor Location: Rail pressure sensors are typically located near the fuel rail or fuel injection pump, allowing them to directly measure the pressure within the system.

- Sensor Construction: Rail pressure sensors consist of a diaphragm or transducer that deforms under the influence of fuel pressure changes. This deformation is converted into an electrical signal proportional to the pressure, which is then transmitted to the ECU for processing.

- How Rail Pressure Sensors Measure Pressure: When fuel pressure changes within the rail, it causes the diaphragm in the sensor to flex. This deformation alters the electrical resistance or capacitance of the sensor, generating a voltage signal that correlates with the pressure changes. The ECU interprets this signal to adjust fuel injection parameters, ensuring optimal engine performance.

Understanding the basics of rail pressure sensors is essential for comprehending their role in modern vehicle engines and their contribution to overall efficiency and performance.

Importance in Engine Performance

Rail pressure sensors are vital components in modern automotive engines, playing a crucial role in optimizing fuel injection, improving engine efficiency, ensuring emission compliance, and enhancing engine longevity. Their importance cannot be overlooked in achieving optimal engine performance and maintaining environmental sustainability.

Optimizing Fuel Injection

Rail pressure sensors are instrumental in optimizing fuel injection processes within automotive engines. By providing real-time data on fuel pressure, these sensors enable precise control over the timing and quantity of fuel delivery to the combustion chamber. This optimization ensures efficient combustion, maximizing power output while minimizing fuel consumption.

Improving Engine Efficiency

The role of rail pressure sensors in improving engine efficiency cannot be overstated. By maintaining the optimal fuel pressure within the fuel rail, these sensors facilitate complete combustion of the fuel-air mixture, resulting in enhanced engine efficiency. Improved efficiency translates to better fuel economy, reduced carbon emissions, and overall smoother engine operation.

Ensuring Emission Compliance

Rail pressure sensors play a crucial role in ensuring compliance with emission regulations. By precisely controlling fuel injection parameters based on real-time pressure data, these sensors help minimize unburned hydrocarbons, carbon monoxide, and nitrogen oxides emitted from the vehicle’s exhaust. This ensures that vehicles equipped with rail pressure sensors meet stringent emission standards, contributing to a cleaner environment.

Impact on Engine Longevity

The proper functioning of rail pressure sensors also has a significant impact on engine longevity. By ensuring optimal fuel delivery and combustion, these sensors help reduce the strain on engine components, minimizing wear and tear over time. Additionally, by preventing issues such as fuel starvation or excessive fuel delivery, rail pressure sensors contribute to the overall health and durability of the engine, prolonging its lifespan.

Common Issues and Troubleshooting

Sensor Failure Symptoms

Rail pressure sensor failures can manifest in various ways, including:

- Engine misfires or hesitation during acceleration.

- Decreased fuel efficiency.

- Illumination of the check engine light.

- Difficulty starting the engine.

- Rough idling or stalling.

Diagnostic Methods

Diagnosing rail pressure sensor issues typically involves:

- Scanning for Error Codes: Using a diagnostic scanner to retrieve trouble codes stored in the engine control unit (ECU) can help pinpoint specific issues related to the rail pressure sensor.

- Checking Fuel Pressure: Utilizing a fuel pressure gauge to measure actual fuel pressure in the rail compared to the expected value can indicate sensor malfunction.

- Visual Inspection: Examining the sensor and its wiring harness for signs of damage, corrosion, or loose connections can identify potential issues.

Repair and Replacement Procedures

If rail pressure sensor issues are confirmed, the following steps may be taken:

- Repair: In some cases, sensor issues may be resolved by cleaning or repairing damaged wiring connections.

- Replacement: If the sensor is found to be faulty or damaged beyond repair, it should be replaced with a new one. This typically involves disconnecting the sensor, removing it from its mounting location, and installing the new sensor in its place. Calibration or reprogramming may be necessary depending on the vehicle’s make and model.

Maintenance and Care Tips

Regular Inspection and Cleaning

Periodic inspection of the rail pressure sensor and its surrounding components is essential. Cleaning any debris or contaminants that may accumulate around the sensor can help prevent malfunction and ensure accurate readings.

Monitoring Rail Pressure Levels

Regularly monitoring fuel rail pressure levels using a diagnostic scanner or gauge can help detect any abnormalities early on. Sudden fluctuations or deviations from normal pressure levels may indicate underlying issues with the sensor or fuel system.

Following Manufacturer Recommendations

Adhering to the manufacturer’s recommended maintenance schedule is crucial for prolonging the lifespan of the rail pressure sensor and ensuring optimal engine performance. Following guidelines for sensor replacement intervals and other maintenance tasks can help prevent issues and minimize downtime.

By following these troubleshooting steps and maintenance tips, vehicle owners can ensure the reliable operation of their rail pressure sensors and maintain peak engine performance.

Future Developments and Trends

The future of rail pressure sensors holds promise for exciting developments in sensor technology, integration with engine management systems, and their impact on the automotive industry as a whole. As these advancements continue to unfold, rail pressure sensors will play a crucial role in shaping the next generation of automotive engines and vehicles.

Advancements in Sensor Technology

The future of rail pressure sensors is poised for significant advancements driven by innovations in sensor technology. These advancements may include:

- Enhanced Accuracy: Continued improvements in sensor accuracy and precision will enable more refined control over fuel injection processes, leading to further gains in engine efficiency and performance.

- Miniaturization: Smaller and more compact sensor designs will allow for easier integration into increasingly compact engine compartments, while also reducing manufacturing costs.

- Multi-Sensor Integration: Integration of rail pressure sensors with other engine sensors and systems, such as oxygen sensors and electronic throttle control, will enable comprehensive engine management and optimization.

Integration with Engine Management Systems

Rail pressure sensors are expected to play an increasingly integral role in engine management systems of the future. This integration will involve:

- Real-Time Data Analytics: Advanced engine management systems will leverage real-time data from rail pressure sensors to dynamically adjust fuel injection parameters based on driving conditions, engine load, and environmental factors.

- Predictive Maintenance: Integration with onboard diagnostics systems will enable predictive maintenance capabilities, allowing for early detection of sensor issues and proactive maintenance to prevent costly breakdowns.

Potential Impact on Automotive Industry

The evolution of rail pressure sensor technology is poised to have a profound impact on the automotive industry:

- Fuel Efficiency and Emissions Reduction: Continued advancements in sensor technology will contribute to improved fuel efficiency and reduced emissions, aligning with global efforts to combat climate change and air pollution.

- Performance and Driver Experience: Enhanced engine management capabilities enabled by rail pressure sensors will lead to smoother, more responsive engine performance, enhancing the overall driving experience for consumers.

- Industry Innovation: As rail pressure sensors become more sophisticated and integral to engine management systems, their development will drive innovation across the automotive industry, fostering competition and pushing the boundaries of technological advancement.

Case Studies and Examples

A. Real-life Examples of Rail Pressure Sensor Failures

- Engine Hesitation and Check Engine Light: In a particular case, a vehicle experienced intermittent engine hesitation accompanied by the illumination of the check engine light. Upon diagnostic examination, it was determined that the rail pressure sensor was failing to provide accurate readings, resulting in improper fuel delivery and engine performance issues.

- Stalling and Hard Starting: Another instance involved a vehicle exhibiting stalling and hard starting symptoms, especially when cold. After thorough inspection, it was discovered that the rail pressure sensor was malfunctioning, causing fuel pressure fluctuations and inconsistencies during startup.

- Reduced Fuel Efficiency: A third example involved a noticeable decrease in fuel efficiency in a vehicle despite regular maintenance. Upon investigation, it was found that the rail pressure sensor was faulty, leading to improper fuel injection timing and excessive fuel consumption.

B. Successful Troubleshooting Scenarios

- Diagnostic Error Code Analysis: In one successful troubleshooting scenario, a technician utilized a diagnostic scanner to retrieve error codes stored in the vehicle’s ECU. By analyzing the error codes related to fuel pressure issues, the technician pinpointed the rail pressure sensor as the likely culprit, facilitating prompt replacement and resolution of the problem.

- Fuel Pressure Gauge Verification: In another scenario, a mechanic diagnosed a rail pressure sensor issue by comparing actual fuel pressure readings from a fuel pressure gauge with the expected values specified by the manufacturer. Deviations from the expected pressure levels confirmed the sensor malfunction, leading to its replacement and restoration of normal engine performance.

- Visual Inspection and Repair: A third successful troubleshooting scenario involved a visual inspection of the rail pressure sensor and its wiring harness. Upon discovering corroded or damaged connections, the technician repaired the wiring and cleaned the sensor, restoring proper functionality without the need for replacement.

These case studies highlight the diverse range of symptoms associated with rail pressure sensor failures and the importance of effective troubleshooting methods in identifying and resolving issues. By employing diagnostic tools, performing thorough inspections, and utilizing appropriate repair techniques, technicians can successfully address rail pressure sensor-related problems and ensure the reliable operation of automotive engines.

Conclusion

Throughout this article, we’ve explored the significance and functions of rail pressure sensors in modern vehicle engines. We discussed the basics of rail pressure sensors, including their definition, types, components, and working principles. We also examined their importance in optimizing fuel injection, improving engine efficiency, ensuring emission compliance, and contributing to engine longevity. Additionally, we covered common issues and troubleshooting methods, maintenance tips, future developments, and real-life case studies.

Importance of Rail Pressure Sensors in Engine Functionality

Rail pressure sensors serve as critical components in automotive engines, playing a vital role in optimizing fuel delivery, enhancing engine performance, and ensuring environmental compliance. By providing real-time data on fuel pressure, these sensors enable precise control over fuel injection processes, resulting in improved efficiency, reduced emissions, and smoother engine operation. Their proper functioning is essential for maintaining optimal engine functionality and prolonging engine lifespan.

Call to Action: Emphasizing the significance of proper maintenance and monitoring for vehicle owners and technicians.

For vehicle owners:

- Regularly inspect your vehicle for any signs of engine performance issues, such as hesitation, rough idling, or decreased fuel efficiency.

- Follow the manufacturer’s recommended maintenance schedule, including routine inspections of the fuel system and rail pressure sensor.

- If you notice any abnormal symptoms or warning lights, seek professional diagnosis and repair to address potential rail pressure sensor issues promptly.

For technicians:

- Stay updated on the latest diagnostic techniques and tools for identifying rail pressure sensor problems.

- Thoroughly inspect the rail pressure sensor and its associated components during routine maintenance checks.

- Educate vehicle owners on the importance of proper maintenance and monitoring to prevent rail pressure sensor failures and ensure optimal engine performance.

By prioritizing proper maintenance and monitoring of rail pressure sensors, both vehicle owners and technicians can contribute to the longevity and reliability of automotive engines, ensuring a smoother driving experience and environmental sustainability.

In conclusion, rail pressure sensors play a pivotal role in the functionality and performance of modern vehicle engines. Understanding their importance, addressing issues promptly, and maintaining them properly are essential for optimal engine operation and longevity.

FAQs

What is a rail pressure sensor, and what does it do?

A rail pressure sensor is a component in automotive engines that measures the pressure of fuel within the fuel rail. It provides real-time data to the engine control unit (ECU), allowing for precise control over fuel injection timing and quantity, thus optimizing engine performance.

What are the common symptoms of a failing rail pressure sensor?

Common symptoms of a failing rail pressure sensor include engine hesitation or misfires, decreased fuel efficiency, difficulty starting the engine, rough idling, and the illumination of the check engine light. These symptoms may indicate issues with fuel delivery and combustion.

How can I diagnose a rail pressure sensor problem?

Diagnosing a rail pressure sensor problem typically involves using a diagnostic scanner to retrieve error codes stored in the ECU, checking fuel pressure using a gauge, and visually inspecting the sensor and its wiring harness for signs of damage or corrosion. These diagnostic methods help pinpoint the cause of engine performance issues related to the rail pressure sensor.

Can a faulty rail pressure sensor affect engine performance?

Yes, a faulty rail pressure sensor can significantly impact engine performance. It can lead to improper fuel delivery, resulting in engine hesitation, reduced power output, decreased fuel efficiency, and increased emissions. Addressing rail pressure sensor issues promptly is essential for maintaining optimal engine functionality.

How often should rail pressure sensors be inspected and maintained?

Rail pressure sensors should be inspected and maintained regularly as part of routine vehicle maintenance. It is recommended to follow the manufacturer’s recommended maintenance schedule, which typically includes periodic inspections of the fuel system and associated components. Additionally, any abnormal symptoms or warning lights should prompt immediate attention from a qualified technician.

Tamara Oldson

23rd Mar 2024Wow! This blog looks exactly like my old one! It’s on a

entirely different subject but it has pretty much the

same layout and design. Superb choice of colors!