Understanding the Importance of DPF Regeneration Inhibit Switch

In today’s ever-evolving automotive landscape, the need for stringent emissions control measures has become paramount. One such innovation that has gained prominence in recent years is the diesel particulate filter (DPF). These filters play a crucial role in reducing harmful emissions from diesel engines, thereby contributing to cleaner air and a healthier environment.

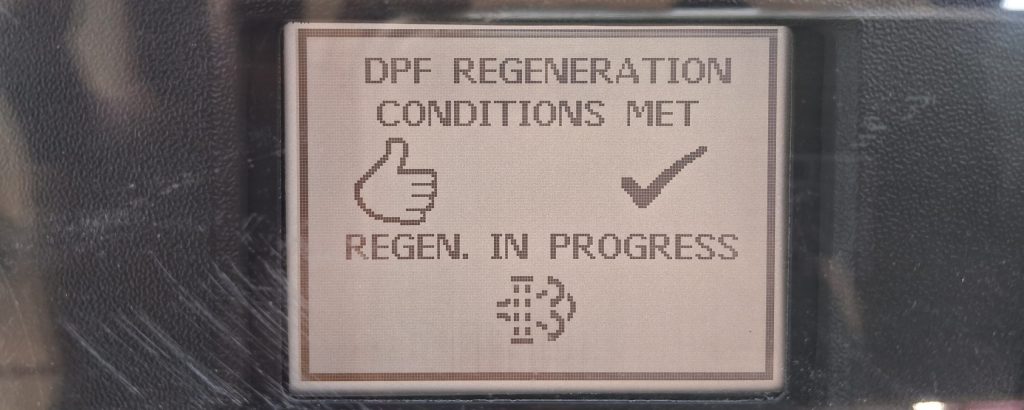

DPF Regeneration: A Vital Process

At the heart of DPF functionality lies the process of regeneration. Over time, as the DPF collects particulate matter from the exhaust gases, it becomes necessary to clean or regenerate the filter to maintain optimal performance. This regeneration process ensures that the DPF remains unclogged, allowing for efficient exhaust flow and continued emission control.

Significance of DPF Regeneration

DPF regeneration not only ensures compliance with emission standards but also preserves engine performance and fuel efficiency. By preventing excessive buildup of particulate matter within the filter, regeneration helps maintain engine longevity and reduces the risk of costly repairs or replacements.

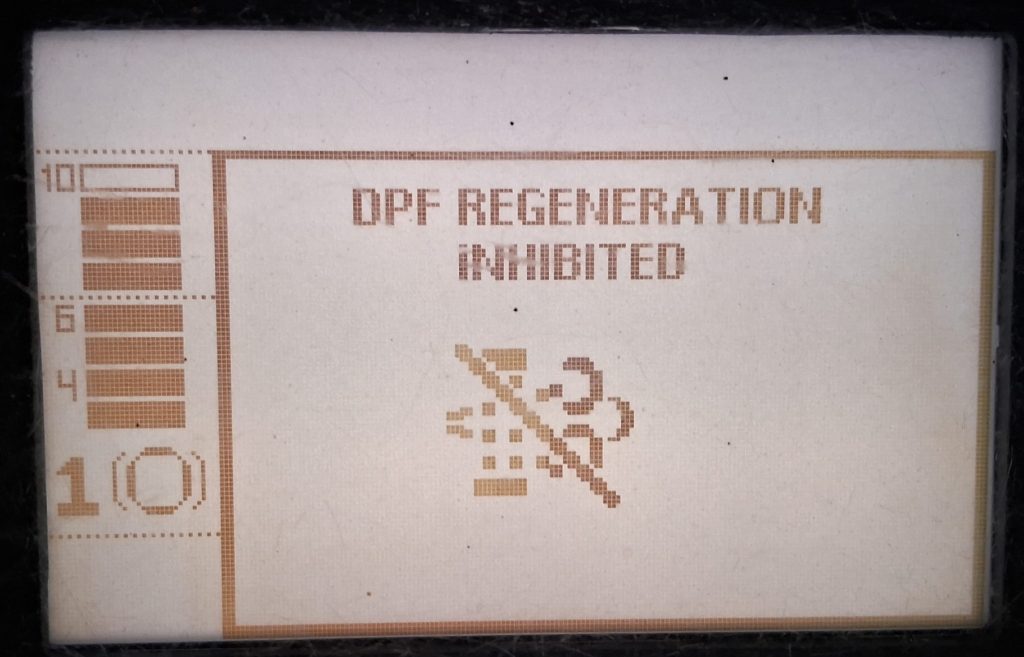

Introducing DPF Regeneration Inhibit Switch (DPF-RIS)

Amidst the various components and mechanisms involved in DPF regeneration, one crucial element is the DPF Regeneration Inhibit Switch (DPF-RIS). This switch provides an additional level of control over the regeneration process, allowing operators to manage regeneration cycles based on specific operational requirements and conditions.

Stay tuned as we delve deeper into the functionality and significance of the DPF Regeneration Inhibit Switch (DPF-RIS) in the subsequent sections.

What is DPF Regeneration?

Diesel particulate filters (DPF) are designed to trap and remove particulate matter (soot) from the exhaust gases of diesel engines. However, over time, the accumulation of soot within the DPF can impede its effectiveness and lead to reduced engine performance and increased emissions. DPF regeneration is the process by which this accumulated soot is burned off, restoring the filter’s capacity and ensuring continued efficient operation.

How DPF Regeneration Works:

DPF regeneration typically involves raising the temperature of the filter to a point where the trapped soot particles are oxidized and converted into harmless gases such as carbon dioxide. This process can occur through two main methods: passive regeneration and active regeneration.

Passive Regeneration:

Passive regeneration occurs naturally during normal driving conditions when exhaust temperatures are sufficiently high to trigger the oxidation of soot within the filter. This process relies on the engine’s operating parameters and does not require any intervention from the vehicle operator.

Active Regeneration:

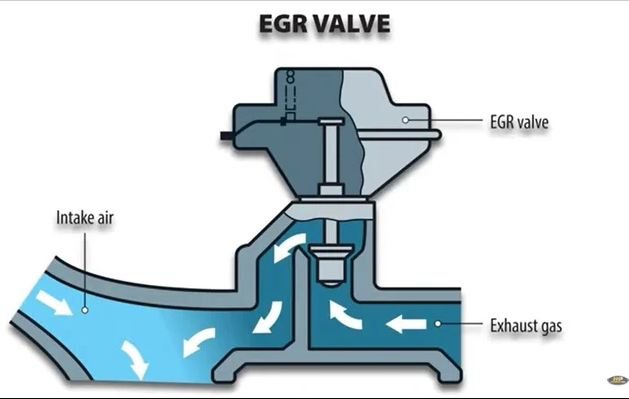

In situations where exhaust temperatures may not reach the necessary levels for passive regeneration to occur, or when the DPF becomes excessively clogged, active regeneration may be initiated. During active regeneration, the engine management system injects additional fuel into the exhaust stream or increases exhaust temperatures through other means, such as a diesel oxidation catalyst (DOC) or a diesel burner, to facilitate the burning off of soot.

Importance of Timely Regeneration:

Timely regeneration is crucial for maintaining DPF longevity and ensuring compliance with emissions regulations. Failure to regenerate the DPF in a timely manner can lead to excessive soot buildup, resulting in reduced engine performance, increased fuel consumption, and potential damage to the DPF itself. Additionally, prolonged intervals between regeneration cycles may result in the activation of warning lights or fault codes, prompting the need for diagnostic and maintenance procedures.

By understanding the mechanisms of DPF regeneration and the importance of timely intervention, vehicle operators can effectively manage DPF performance and contribute to cleaner air quality and sustainable transportation practices.

Understanding the DPF Regeneration Inhibit Switch (DPF-RIS)

The DPF Regeneration Inhibit Switch (DPF-RIS) is a critical component of modern diesel engine systems, offering operators a level of control over the DPF regeneration process. Let’s explore its definition, purpose, functionality, and significance in various driving conditions and maintenance scenarios.

Definition and Purpose of DPF-RIS:

The DPF-RIS is a switch integrated into the vehicle’s control system, allowing operators to selectively inhibit or postpone DPF regeneration cycles. Its primary purpose is to provide flexibility and control over regeneration processes based on specific operational requirements and conditions.

Functionality: How DPF-RIS Allows Control Over Regeneration Processes:

When activated, the DPF-RIS communicates with the engine management system to delay or inhibit the initiation of DPF regeneration. This prevents regeneration cycles from occurring during critical operational periods or in situations where regeneration may not be practical or desirable, such as during short trips or idling periods.

When and Why Would the DPF-RIS Be Used?

The DPF-RIS is typically utilized in scenarios where immediate regeneration is not feasible or advantageous. For example:

- Urban Driving: In stop-and-go traffic or urban environments where exhaust temperatures may not reach the required levels for effective regeneration, the DPF-RIS can be used to postpone regeneration until the vehicle is operating under conditions more conducive to the process.

- Low Load or Idle Conditions: During extended periods of low engine load or idling, such as when stationary at traffic lights or during extended vehicle downtime, activating the DPF-RIS can prevent unnecessary fuel consumption and heat generation associated with regeneration.

- Maintenance Scenarios: In certain maintenance scenarios, such as when performing engine repairs or diagnostic procedures, inhibiting DPF regeneration via the DPF-RIS can help avoid potential safety hazards or interference with ongoing maintenance tasks.

Importance of DPF-RIS in Certain Driving Conditions or Maintenance Scenarios:

The DPF-RIS plays a crucial role in optimizing vehicle performance, fuel efficiency, and emissions control under diverse operating conditions. By allowing operators to selectively control DPF regeneration, the switch helps mitigate potential drawbacks associated with regeneration, such as increased fuel consumption and engine wear, while ensuring compliance with emissions regulations.

In conclusion, the DPF Regeneration Inhibit Switch (DPF-RIS) offers valuable flexibility and control over DPF regeneration processes, enabling operators to manage regeneration cycles effectively in various driving conditions and maintenance scenarios, thereby enhancing overall vehicle performance and sustainability.

Benefits and Risks Associated with DPF Regeneration Inhibit Switch

As with any technology or feature in automotive systems, the DPF Regeneration Inhibit Switch (DPF-RIS) offers both benefits and risks. Let’s explore these aspects in detail:

Benefits:

- Improved Fuel Efficiency in Certain Driving Conditions:

By allowing operators to postpone regeneration cycles during low-load or idle conditions, the DPF-RIS can contribute to improved fuel efficiency. This is particularly beneficial in urban driving environments or during extended periods of idling where regeneration may result in unnecessary fuel consumption. - Preventing Unnecessary Regeneration Cycles:

The DPF-RIS provides operators with the ability to prevent regeneration cycles from occurring at inappropriate times, such as during short trips or when the engine is not operating at optimal temperatures. This helps conserve fuel and reduces wear on engine components associated with frequent regeneration. - Enhanced Control Over DPF Maintenance:

With the DPF-RIS, operators have greater control over DPF maintenance schedules, allowing regeneration to be timed based on operational requirements and maintenance intervals. This ensures that regeneration occurs when it is most effective and minimizes the risk of unexpected downtime due to DPF-related issues.

Risks:

- Potential for Increased Emissions if Used Improperly:

Improper use of the DPF-RIS, such as consistently inhibiting regeneration cycles without consideration for emissions control, can lead to increased emissions of harmful pollutants. This is especially concerning in regions with strict emissions regulations, where non-compliance can result in penalties or fines. - Negative Impacts on DPF Health if Inhibit Switch is Abused:

Excessive or indiscriminate use of the DPF-RIS can have detrimental effects on the health and longevity of the diesel particulate filter. Delaying regeneration cycles for extended periods may cause the DPF to become excessively clogged, leading to reduced efficiency, increased back pressure, and potential damage to the filter substrate.

While the DPF Regeneration Inhibit Switch offers operators valuable control over DPF regeneration processes, it is essential to use this feature judiciously and in accordance with manufacturer recommendations. When utilized responsibly, the DPF-RIS can help optimize fuel efficiency, prolong DPF life, and enhance overall vehicle performance. However, improper use can result in adverse environmental impacts and compromise DPF functionality, underscoring the importance of informed and responsible operation.

Best Practices for Using the DPF Regeneration Inhibit Switch

Proper utilization of the DPF Regeneration Inhibit Switch (DPF-RIS) is essential for optimizing vehicle performance, maintaining emissions compliance, and preserving the longevity of the diesel particulate filter (DPF). Here are some best practices to guide operators in the effective use of the DPF-RIS:

Guidance for Proper Utilization:

- Understand Operational Conditions:

Familiarize yourself with the driving conditions and operational parameters that affect DPF regeneration. This includes factors such as engine load, exhaust temperatures, and driving patterns. - Follow Manufacturer Recommendations:

Adhere to the recommendations provided by the vehicle manufacturer regarding DPF maintenance and regeneration procedures. Consult the owner’s manual or seek guidance from authorized service technicians for specific instructions. - Exercise Judicious Control:

Use the DPF-RIS judiciously, activating or deactivating the switch based on the prevailing driving conditions and operational requirements. Avoid prolonged inhibition of regeneration cycles unless absolutely necessary.

Situations Where Activating or Deactivating the Switch is Advisable:

- Urban Driving or Low-Speed Conditions:

In situations where exhaust temperatures may not reach optimal levels for passive regeneration, activating the DPF-RIS can help prevent unnecessary regeneration cycles during low-speed driving or frequent stops. - Extended Idle Periods:

When the vehicle is stationary for extended periods, such as during idling or prolonged stops, consider deactivating the DPF-RIS to allow for regeneration cycles to occur and prevent excessive soot buildup. - Maintenance or Diagnostic Procedures:

During maintenance or diagnostic procedures that require extended engine operation or idle periods, temporarily deactivate the DPF-RIS to facilitate regeneration and prevent potential issues related to soot accumulation.

Importance of Understanding Manufacturer Recommendations:

- Optimal Performance and Reliability:

Following manufacturer recommendations ensures that the DPF-RIS is used in a manner that promotes optimal performance, reliability, and longevity of the DPF and associated engine components. - Emissions Compliance:

Adhering to manufacturer guidelines helps maintain compliance with emissions regulations, minimizing the risk of excessive pollutant emissions and potential regulatory violations. - Warranty Considerations:

Deviating from manufacturer recommendations may void warranty coverage for DPF-related issues or engine damage resulting from improper use of the DPF-RIS. Ensure compliance with warranty terms to avoid potential financial liabilities.

Proper utilization of the DPF Regeneration Inhibit Switch is essential for maximizing vehicle efficiency, emissions control, and DPF longevity. By understanding operational conditions, following manufacturer recommendations, and exercising judicious control over the switch, operators can effectively manage DPF regeneration processes and contribute to sustainable and responsible vehicle operation.

Maintenance Considerations

Proper maintenance of the diesel particulate filter (DPF) system is crucial for ensuring optimal performance and longevity. Here are some important maintenance considerations:

Regular Inspection and Maintenance of DPF System:

- Scheduled Inspections: Follow manufacturer recommendations for scheduled inspections of the DPF system. Regular checks can help detect potential issues early and prevent costly repairs or replacements.

- Filter Cleaning: Depending on driving conditions and vehicle usage, the DPF may require periodic cleaning to remove accumulated soot. Follow manufacturer guidelines for proper cleaning procedures.

- Sensor Calibration: Ensure that sensors associated with the DPF system, such as temperature and pressure sensors, are calibrated and functioning correctly to maintain accurate monitoring and control of regeneration processes.

Impact of DPF-RIS Usage on Overall Maintenance Schedule:

- Monitoring Frequency: When using the DPF Regeneration Inhibit Switch (DPF-RIS), monitor the DPF system more frequently for signs of soot buildup or potential issues. Adjust maintenance intervals as needed based on usage patterns and operational conditions.

- Scheduled Regeneration: Incorporate scheduled regeneration cycles into the maintenance schedule, especially if the DPF-RIS is frequently activated to postpone regeneration during normal driving.

Signs of DPF-Related Issues and Troubleshooting Strategies:

- Increased Exhaust Backpressure: Monitor for signs of increased exhaust backpressure, which may indicate a partially or fully clogged DPF. Address the issue promptly to prevent engine performance issues.

- Warning Lights or Fault Codes: Pay attention to warning lights on the dashboard or diagnostic trouble codes (DTCs) related to the DPF system. Use diagnostic tools to identify the underlying cause and take appropriate action.

- Abnormal Engine Performance: Any noticeable decrease in engine performance or unusual noises may indicate DPF-related issues. Conduct a thorough inspection to identify and address the root cause.

Regulations and Compliance

Compliance with emissions regulations is essential for ensuring environmental protection and regulatory compliance. Here’s an overview of regulations pertaining to DPF systems and considerations for using the DPF-RIS:

Overview of Emissions Regulations Pertaining to DPF Systems:

- Emission Standards: Many regions have established emissions standards that vehicles must meet, including regulations specific to particulate matter emissions from diesel engines.

- DPF Requirements: Some jurisdictions mandate the use of DPF systems on diesel vehicles to reduce particulate emissions. Compliance with DPF installation and functionality requirements is essential.

Compliance Considerations When Utilizing the DPF-RIS:

- Monitoring and Reporting: Operators should ensure that the use of the DPF-RIS complies with local regulations and reporting requirements. Maintain records of DPF maintenance and regeneration activities as needed for regulatory compliance.

- Emissions Testing: Vehicles equipped with DPF systems may be subject to periodic emissions testing to verify compliance with regulatory standards. Ensure that the DPF-RIS usage does not compromise emissions performance during testing.

Importance of Adherence to Local Regulations and Standards:

- Environmental Protection: Adherence to emissions regulations helps protect public health and the environment by reducing harmful pollutants emitted from diesel vehicles, including particulate matter.

- Legal Compliance: Failure to comply with emissions regulations can result in penalties, fines, or vehicle registration restrictions. Ensure that the DPF system, including the use of the DPF-RIS, meets all applicable regulatory requirements.

Proper maintenance of the DPF system, adherence to emissions regulations, and responsible use of the DPF Regeneration Inhibit Switch are essential for maintaining vehicle performance, ensuring regulatory compliance, and minimizing environmental impact. Stay informed about local regulations and follow manufacturer guidelines for optimal DPF system operation and maintenance.

Future Trends and Developments

As technology continues to evolve, advancements in diesel particulate filter (DPF) technology and associated systems are expected to shape the future of emissions control in the automotive industry. Here are some potential future trends and developments:

Advances in DPF Technology and Regeneration:

- Efficiency Improvements: Future DPF designs may focus on enhancing filtration efficiency and reducing pressure drop across the filter, thereby improving overall engine performance and fuel economy.

- Alternative Regeneration Methods: Research is ongoing into alternative regeneration methods, such as microwave or plasma-assisted regeneration, which could offer faster and more efficient cleaning of the DPF without relying solely on thermal regeneration.

- Sensor Integration: Continued advancements in sensor technology may enable more precise monitoring of DPF performance and exhaust emissions, allowing for optimized regeneration strategies tailored to specific driving conditions.

Potential Improvements or Variations of the DPF-RIS:

- Adaptive Control Systems: Future iterations of the DPF Regeneration Inhibit Switch may incorporate adaptive control algorithms that dynamically adjust regeneration cycles based on real-time sensor data, driving conditions, and vehicle usage patterns.

- Remote Monitoring and Control: Integration with telematics systems could enable remote monitoring and control of the DPF-RIS, allowing fleet managers or service technicians to optimize regeneration processes and troubleshoot issues remotely.

- Enhanced User Interface: Improved user interfaces and diagnostic tools may provide operators with more comprehensive information and control over DPF regeneration, simplifying the management of the DPF-RIS.

Integration with Emerging Automotive Technologies:

- Electric Vehicles (EVs): While DPF technology is primarily associated with diesel engines, future developments may explore the integration of emissions control systems with hybrid or range-extended electric vehicles that incorporate combustion engines.

- Hybrid Powertrains: Hybrid powertrains, combining internal combustion engines with electric propulsion, may benefit from advanced DPF systems that optimize emissions control during both engine and electric propulsion modes.

- Connected Vehicles: Integration with connected vehicle platforms could enable seamless communication between the DPF system, engine management system, and external data sources, allowing for more intelligent and adaptive regeneration strategies.

Conclusion

In conclusion, diesel particulate filter (DPF) regeneration plays a crucial role in emissions control, ensuring compliance with environmental regulations and maintaining air quality. The DPF Regeneration Inhibit Switch (DPF-RIS) offers operators valuable control over regeneration processes, balancing efficiency, emissions control, and DPF maintenance.

By understanding the importance of DPF regeneration, recognizing the significance of the DPF-RIS, and staying informed about future trends and developments in DPF technology, stakeholders can contribute to sustainable and responsible vehicle operation in the evolving automotive landscape. As advancements continue to drive innovation, the integration of DPF systems with emerging automotive technologies holds promise for further enhancing environmental performance and efficiency in the years to come.