Revolutionizing Cooling Systems: The Rise of Electronic Viscous Fan Speed Sensors

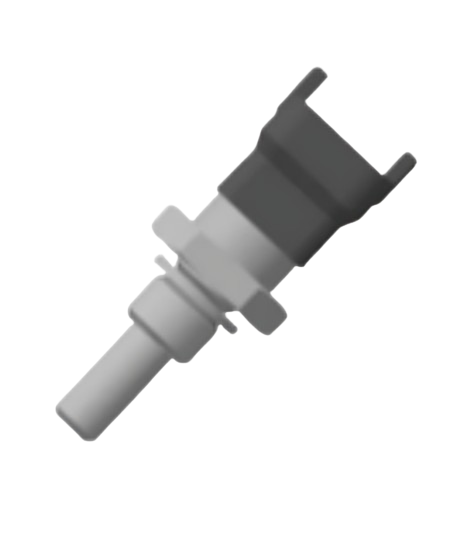

The electronic viscous fan speed sensors, commonly referred to as the EV fan speed sensor, is a crucial component in modern automotive and industrial cooling systems. It is designed to monitor and regulate the speed of the fan, ensuring optimal cooling performance under varying conditions.

Importance in Automotive and Industrial Applications

In both automotive and industrial settings, maintaining optimal operating temperatures is essential for the performance, efficiency, and longevity of machinery. The EV fan speed sensor plays a pivotal role in this regard by continuously monitoring the temperature and adjusting the fan speed accordingly. This proactive approach not only ensures efficient cooling but also prevents overheating, which can lead to costly damages and downtime.

Significance of Efficient Cooling Systems

Efficient cooling systems are paramount in various applications to dissipate heat generated during operation. Whether it’s in an automobile engine, heavy machinery, or industrial equipment, excess heat can compromise performance, accelerate wear and tear, and even cause catastrophic failures. By employing advanced technologies like the EV fan speed sensor, manufacturers can enhance the reliability, efficiency, and durability of their cooling systems, thereby optimizing overall performance and reducing maintenance costs.

Understanding Electronic Viscous Fan Speed Sensors

How Electronic Viscous Fan Speed Sensors Work

Electronic viscous fan speed sensors operate on the principle of detecting rotational speed variations of the fan blades. They typically utilize magnetic sensors or Hall effect sensors to monitor the movement of a magnetized rotor attached to the fan assembly. As the fan rotates, the sensor detects changes in magnetic field strength, converting these fluctuations into electrical signals that are interpreted by the control unit.

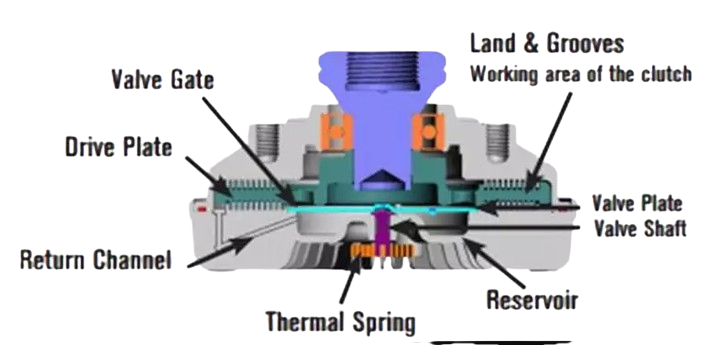

Components and Functionality Explained

Electronic viscous fan speed sensors comprise several key components, including the sensor itself, a magnetized rotor, wiring harness, and the control unit. The sensor is strategically positioned to detect the rotational speed of the fan blades, while the magnetized rotor is affixed to the fan assembly. When the fan rotates, the magnetic field around the rotor fluctuates, triggering the sensor to generate electrical signals proportional to the fan speed. These signals are then transmitted to the control unit, which regulates the operation of the fan motor based on predetermined algorithms and temperature inputs.

Comparison with Traditional Fan Speed Sensors

In contrast to traditional fan speed sensors, which rely on mechanical mechanisms such as bimetallic strips or fluid-filled chambers, electronic viscous fan speed sensors offer several advantages. They provide greater accuracy, responsiveness, and flexibility in regulating fan speed, resulting in more precise temperature control and improved energy efficiency. Additionally, electronic sensors are less susceptible to wear and tear compared to their mechanical counterparts, resulting in enhanced reliability and longevity. Overall, electronic viscous fan speed sensors represent a significant advancement in cooling system technology, offering superior performance and reliability in automotive and industrial applications.

Advantages of Electronic Viscous Fan Speed Sensors

electronic viscous fan speed sensors offer a multitude of advantages, including enhanced efficiency, precision control, reduced power consumption, and adaptability to varying environmental conditions. By leveraging advanced technology and real-time data, these sensors play a crucial role in optimizing cooling system performance and improving overall reliability in automotive and industrial applications.

Enhanced Efficiency in Cooling Systems

Electronic viscous fan speed sensors play a pivotal role in enhancing the efficiency of cooling systems by precisely regulating fan speed according to the specific cooling requirements. Unlike traditional fan speed control methods that operate on fixed speeds or rudimentary temperature thresholds, electronic sensors offer dynamic adjustments based on real-time data. This ensures optimal cooling performance across a wide range of operating conditions, resulting in improved thermal management and overall system efficiency.

Precision Control and Monitoring Capabilities

One of the key advantages of electronic viscous fan speed sensors is their ability to provide precise control and monitoring capabilities. By continuously monitoring factors such as engine temperature, ambient conditions, and workload demands, these sensors can adjust fan speed with unparalleled accuracy. This precision enables cooling systems to respond swiftly to temperature fluctuations, preventing overheating and maintaining optimal operating conditions. Additionally, electronic sensors facilitate comprehensive diagnostic capabilities, allowing for early detection of potential issues and proactive maintenance measures.

Reduced Power Consumption

Electronic viscous fan speed sensors contribute to reduced power consumption by optimizing fan speed based on actual cooling requirements. Unlike traditional cooling systems that operate at fixed speeds or rely on mechanical controls, electronic sensors can dynamically adjust fan speed to match the current workload and environmental conditions. This intelligent regulation minimizes unnecessary energy expenditure, resulting in lower fuel consumption in automotive applications and reduced electricity usage in industrial settings. By optimizing power usage without compromising cooling effectiveness, electronic sensors help improve overall energy efficiency and reduce operating costs.

Adaptability to Varying Environmental Conditions

Another significant advantage of electronic viscous fan speed sensors is their adaptability to varying environmental conditions. Whether operating in extreme temperatures, high altitudes, or challenging terrain, these sensors can dynamically adjust fan speed to maintain optimal cooling performance. This adaptability ensures consistent and reliable cooling operation across diverse operating environments, enhancing system reliability and longevity. Additionally, electronic sensors can incorporate additional inputs such as humidity, airflow, and vehicle speed to further optimize cooling performance under varying conditions.

Applications in the Automotive Industry

Role in Engine Cooling Systems

Electronic viscous fan speed sensors are integral components of engine cooling systems in the automotive industry. They regulate the speed of cooling fans, ensuring optimal airflow to dissipate heat generated during engine operation. By maintaining the engine at the ideal operating temperature, these sensors contribute to engine longevity, reliability, and performance.

Impact on Fuel Efficiency and Emissions Control

Efficient engine cooling, facilitated by electronic viscous fan speed sensors, plays a significant role in improving fuel efficiency and emissions control in vehicles. By preventing overheating and optimizing engine operating temperatures, these sensors help reduce fuel consumption and minimize harmful emissions. This contributes to environmental sustainability and regulatory compliance in the automotive sector.

Integration in Electric Vehicles

Electronic viscous fan speed sensors are also essential in electric vehicles (EVs) where efficient thermal management is critical for battery performance and longevity. These sensors regulate cooling fans to maintain optimal battery temperatures, ensuring safe and reliable operation. Additionally, they contribute to overall energy efficiency by optimizing cooling system performance in EVs, thereby extending driving range and enhancing vehicle reliability.

Industrial Implementations

Electronic viscous fan speed sensors play critical roles in both automotive and industrial applications, contributing to enhanced performance, efficiency, and reliability. From regulating engine temperatures in vehicles to optimizing cooling systems in industrial machinery, these sensors are essential components in modern thermal management solutions.

Utilization in HVAC Systems

In industrial settings, electronic viscous fan speed sensors find widespread application in heating, ventilation, and air conditioning (HVAC) systems. These sensors regulate fan speeds to maintain desired temperatures and airflow rates, ensuring comfortable and controlled environments in commercial buildings, factories, and other facilities.

Benefits for Machinery and Equipment Cooling

Electronic viscous fan speed sensors play a crucial role in cooling machinery and equipment in various industrial applications. From heavy-duty machinery to precision manufacturing equipment, these sensors optimize cooling performance, prevent overheating, and enhance operational reliability. By maintaining optimal operating temperatures, they contribute to prolonged equipment lifespan and reduced maintenance costs.

Case Studies and Real-World Examples

Numerous case studies and real-world examples highlight the effectiveness of electronic viscous fan speed sensors in automotive and industrial applications. From improved engine performance and fuel efficiency in automobiles to enhanced productivity and reliability in industrial machinery, these sensors have demonstrated significant benefits across diverse sectors. Case studies provide empirical evidence of the positive impact of electronic sensors on cooling system performance, energy efficiency, and overall operational effectiveness.

Challenges and Future Developments

Addressing Reliability Concerns

Despite their numerous benefits, electronic viscous fan speed sensors face challenges related to reliability, durability, and performance in harsh operating conditions. Ensuring robustness and longevity of these sensors remains a priority for manufacturers, requiring advancements in materials, design, and testing methodologies.

Potential Technological Advancements

Future developments in electronic viscous fan speed sensors are likely to focus on enhancing reliability, precision, and efficiency. Innovations such as advanced sensor technologies, predictive analytics, and integration with intelligent control systems hold promise for optimizing cooling system performance and addressing evolving industry needs.

Market Trends and Predictions

The market for electronic viscous fan speed sensors is expected to witness steady growth, driven by increasing demand for energy-efficient cooling solutions in automotive, industrial, and HVAC applications. Emerging trends such as electrification, autonomous vehicles, and Industry 4.0 are likely to further propel the adoption of these sensors across diverse industries.

Conclusion

Electronic viscous fan speed sensors play critical roles in optimizing cooling system performance and efficiency in automotive and industrial applications. From regulating engine temperatures to maintaining optimal operating conditions in machinery and equipment, these sensors contribute to enhanced reliability, energy efficiency, and overall performance.

Affirmation of the Importance of Electronic Viscous Fan Speed Sensors

The importance of electronic viscous fan speed sensors cannot be overstated, as they enable precise control, monitoring, and optimization of cooling systems. By preventing overheating, improving energy efficiency, and enhancing equipment reliability, these sensors are indispensable components in modern thermal management solutions.

Outlook for Continued Innovation and Application in Diverse Industries

Looking ahead, electronic viscous fan speed sensors are poised to continue evolving and finding new applications across diverse industries. Continued innovation in sensor technology, coupled with advancements in data analytics and automation, will further enhance their effectiveness and versatility. As industries strive for greater efficiency, sustainability, and performance, electronic viscous fan speed sensors will play an increasingly vital role in shaping the future of cooling systems worldwide.

More Article- The Role of Engine Management Systems (EMS) : Optimizing Power and Efficiency

FAQs (Frequently Asked Questions)

What is the purpose of an electronic viscous fan speed sensor?

An electronic viscous fan speed sensor is designed to monitor and regulate the speed of cooling fans in automotive and industrial applications. By adjusting fan speed according to temperature variations, these sensors ensure efficient cooling and prevent overheating.

How does an electronic viscous fan speed sensor work?

Electronic viscous fan speed sensors typically utilize magnetic sensors or Hall effect sensors to detect the rotational speed of fan blades. As the fan rotates, changes in magnetic field strength are detected and converted into electrical signals, which are then interpreted by the control unit to regulate fan speed.

What are the benefits of using electronic viscous fan speed sensors?

Electronic viscous fan speed sensors offer several advantages, including enhanced efficiency in cooling systems, precision control and monitoring capabilities, reduced power consumption, and adaptability to varying environmental conditions. These sensors contribute to improved performance, reliability, and energy efficiency in automotive and industrial applications.

Are electronic viscous fan speed sensors suitable for electric vehicles (EVs)?

Yes, electronic viscous fan speed sensors are essential components in electric vehicles (EVs) where efficient thermal management is critical for battery performance and longevity. These sensors regulate cooling fans to maintain optimal battery temperatures, ensuring the safe and reliable operation and contributing to overall energy efficiency.

What challenges do electronic viscous fan speed sensors face, and how are they being addressed?

Electronic viscous fan speed sensors face challenges related to reliability, durability, and performance in harsh operating conditions. Manufacturers are addressing these challenges through advancements in materials, design, and testing methodologies to ensure robustness and longevity of these sensors in automotive and industrial applications.